CNC machining process: G-code writing examples for aluminum alloy 3D parts and plastic molds

🧭 1. Initial Preparation Stage

1. Design Drawings (CAD)

Use CAD software (e.g., AutoCAD, SolidWorks, Fusion 360) to create 2D or 3D part drawings.

The drawings should clearly indicate dimensions, tolerances, materials, and other technical details.

2. Process Planning and Analysis

- Determine the machining sequence (e.g., roughing → semi-finishing → finishing).

- Select appropriate machining equipment (e.g., CNC lathe, milling machine, machining center).

- Choose suitable tools, fixtures, and coolants based on the material and design requirements.

🧮 2. Programming Stage

3. CAM Programming (Computer-Aided Manufacturing)

- Use CAM software (e.g., Mastercam, UG NX, Fusion 360) to generate toolpaths based on the CAD model.

- Set machining parameters such as spindle speed, feed rate, and depth of cut.

- Generate CNC machining code (G-code / NC code).

4. Simulation and Verification

- Perform virtual simulation using CAM software or directly on the CNC machine.

- Check for potential issues such as tool collisions, overcuts, and interference problems.

🏗️ 3. Machine Setup Stage

5. Equipment Setup and Calibration

- Install tools and apply tool length and radius offsets.

- Mount fixtures and securely clamp the workpiece.

- Set up the work coordinate system (e.g., G54, G55, etc.).

- Transfer the NC program to the CNC controller.

🛠️ 4. Actual Machining Stage

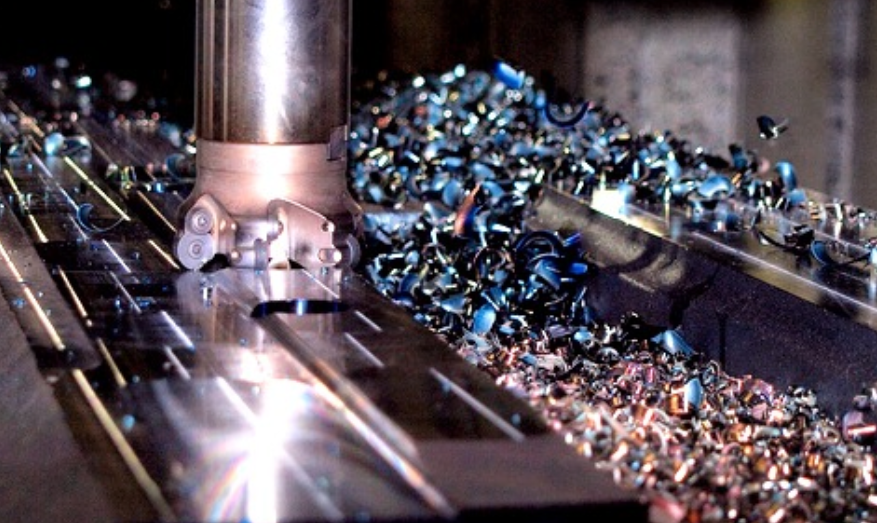

6. Machining Operation

- Perform a dry run or trial cut to verify the program is correct.

- Start the actual machining process under operator supervision.

- Monitor for tool wear, coolant flow, abnormal sounds, and any unexpected behavior during cutting.

🔍 5. Inspection and Post-Processing Stage

7. Quality Inspection

- Use measuring instruments (e.g., calipers, coordinate measuring machines) to check part dimensions, tolerances, and geometric accuracy.

- Confirm that all critical dimensions meet specifications.

8. Surface and Post-Processing (As Required)

- Processes may include deburring, grinding, sandblasting, anodizing, electroplating, etc.

9. Cleaning, Packaging, and Shipping

- Clean the finished parts to remove cutting fluids and burrs.

- Package, label, and ship according to customer requirements.

✅ Simplified CNC Machining Workflow Diagram:

mathematica複製編輯Design Drawing → Process Planning → Program Generation → Machine Setup → Trial Run & Verification → Machining → Quality Check → Surface Treatment → Shipping

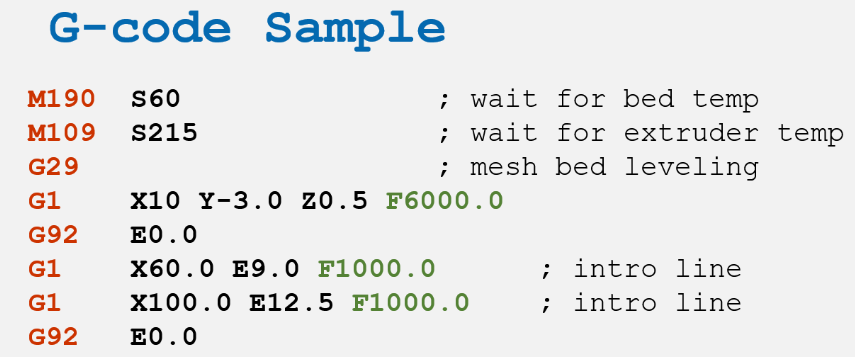

✳️ 1. G-code Examples and Explanation

G-code (also known as numerical control code) is the programming language used by CNC machines to execute machining operations. Common commands include:

Command Function Description

G00 Rapid movement (non-cutting)

G01 Linear interpolation (cutting move)

G02 Clockwise arc interpolation

G03 Counterclockwise arc interpolation

G17/G18/G19 Select working plane (XY/XZ/YZ)

G90 Absolute coordinate system (commonly used)

G91 Incremental coordinate system

M03 Spindle clockwise rotation

M05 Spindle stop

M06 Tool change

M30 End of program and reset

✅ Simple G-code Example (Milling a 50x50 mm square):

gcode

複製

編輯

G90 G17 G21 ; Absolute programming, XY plane, units in mm

G00 X0 Y0 ; Rapid move to start point

M06 T1 ; Load tool #1

M03 S1200 ; Spindle on CW at 1200 rpm

G01 Z-2.0 F100 ; Plunge into material 2mm deep at 100 mm/min

G01 X50 Y0 F300 ; Cut along X-axis 50 mm

G01 X50 Y50 ; Cut along Y-axis 50 mm

G01 X0 Y50 ; Cut back along X-axis

G01 X0 Y0 ; Return to start point to complete square

G00 Z10 ; Retract to safe height

M05 ; Stop spindle

M30 ; End of program

📌 Note: This is a basic example. Actual programs must be adapted to part design and machine specifications.

🔧 2. Tool Types and Their Uses

Different machining operations require different types of cutting tools. Below are common CNC tools:

Tool Name Appearance Application Features

End Mill Cylindrical Surface, slot, contour milling Can cut side and bottom surfaces; common

Ball Nose End Mill Hemispherical tip Surface finishing, 3D models Smooth finish, high precision

Bull Nose Mill Rounded corner Semi-finishing 3D surfaces Stronger than ball nose, ideal for roughing

Drill Bit Tapered point Hole drilling For standard hole-making

Boring Tool Single-point tool Precision internal boring Improves hole diameter and finish

Thread Mill Thread-shaped flutes Thread hole machining High precision, usable for blind holes

Chamfer Mill Angled edges Chamfering and deburring Ideal for edge finishing

🧠 3. Machining Strategies (Cutting Methods and Sequences)

A well-planned machining strategy enhances both efficiency and quality. Below are standard strategies:

1. Machining Sequence Planning

Step Machining Type Description

1 Roughing Remove large material volume, basic shape

2 Semi-finishing Refine geometry, improve dimensional accuracy

3 Finishing Final dimensions and surface roughness

4 Surface Treatment Deburring, chamfering, coating, etc.

2. Cutting Strategy Types

Strategy Type Description Best Used For

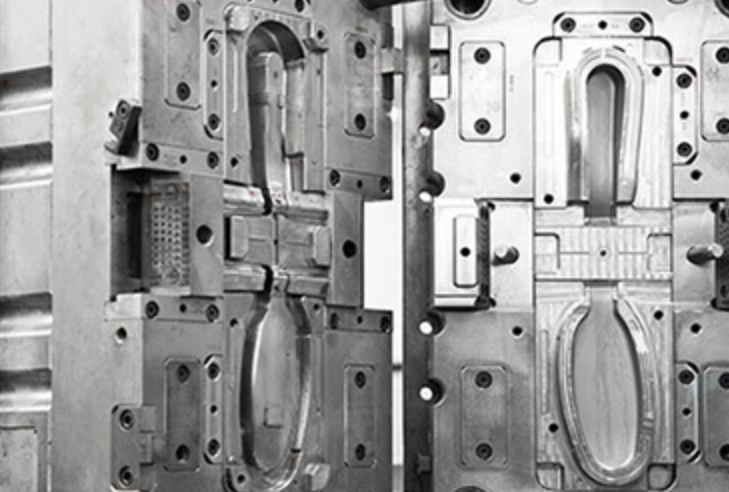

Z-level machining Layered cuts along Z-axis 3D surface machining, commonly in mold making

Contour machining Moves along outer profiles 2D profiles, part outlines

Rest machining Targets small areas missed by larger tools Used in finishing stages

Facing Flattens the material surface Initial operation, creates reference surface

Helical ramping Spiral entry to reduce tool stress Deep holes, hard materials

Adaptive clearing Constant-load intelligent pathing Common in CAM, increases tool life

🔚 Summary

Topic Key Concepts

G-code Programming language for CNC; must be precise and verified

Cutting Tools Tool choice affects machining precision, surface finish, and efficiency

Machining Strategy Core to balancing speed and quality; structured in progressive stages

#Loading and unloading machine slide rail #AI automatic stacking robot arm

#Yongyi Technology #Automated special machine manufacturing #Automated arm handling loading and unloading #Automated inspection and assembly

#Robot suction cup gripper series #CNC precision component manufacturing #Semiconductor automation component supply #Stainless steel aluminum alloy carbon steel copper alloy

#Engineering plastics #Sheet metal welding group #Ceramic quartz processing #Customized fixture design, manufacturing and development #Customer assembly service

#Slide table fine adjustment table system #Digital microscope #Aluminum extrusion trolley #Japanese NPM series products

#Semiconductor components #Automation equipment components #CNC machining #Robot arm loading and unloading #Automatic loading and unloading equipment #Smart manufacturing #Automated production line #Smart factory #Automated equipment

#CNC machining #CNC precision machining #Semiconductor components #Automation equipment #Precision components #Robot arm #Stainless steel machining #Engineering plastics #Ceramic machining

Yongyi Technology