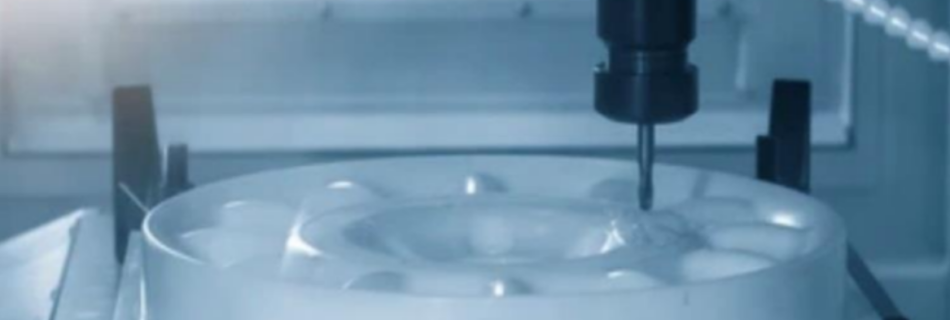

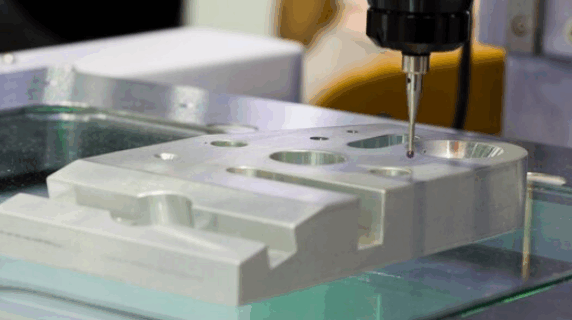

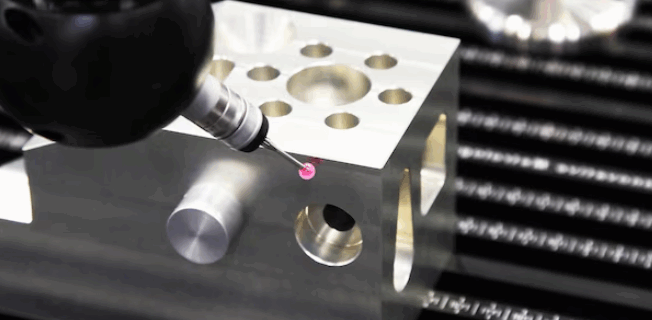

CNC machining process: G-code writing examples for aluminum alloy 3D parts and plastic molds

CNC machining process: G-code writing examples for aluminum alloy 3D parts and plastic molds 🧭 1. Initial Preparation Stage 1. Design Drawings (CAD) Use CAD software (e.g., AutoCAD, SolidWorks, Fusion 360) to create 2D or 3D part drawings.The drawings should clearly indicate dimensions, tolerances, materials, and other technical details. 2. Process Planning and Analysis 🧮 …