CNC Machining Expertise + Robotic Automation + System Integration + Quality Control + Digital Tools

to Achieve the True “1+1 > 2” Synergy

CNC × Automation Professional Workflow

1️⃣ CNC Machining Expertise — Building the Foundation

- Workpiece Analysis: Material properties (aluminum, titanium alloys, engineering plastics…)

- Process Planning: Determining turning, milling, drilling, grinding sequences

- Tooling & Fixture Design: Ensuring stable machining and compatibility with automation

- Optimized Machining Parameters: Balancing efficiency, surface finish, and precision

👉 Role: Ensures machining accuracy and stability, laying the groundwork for automation.

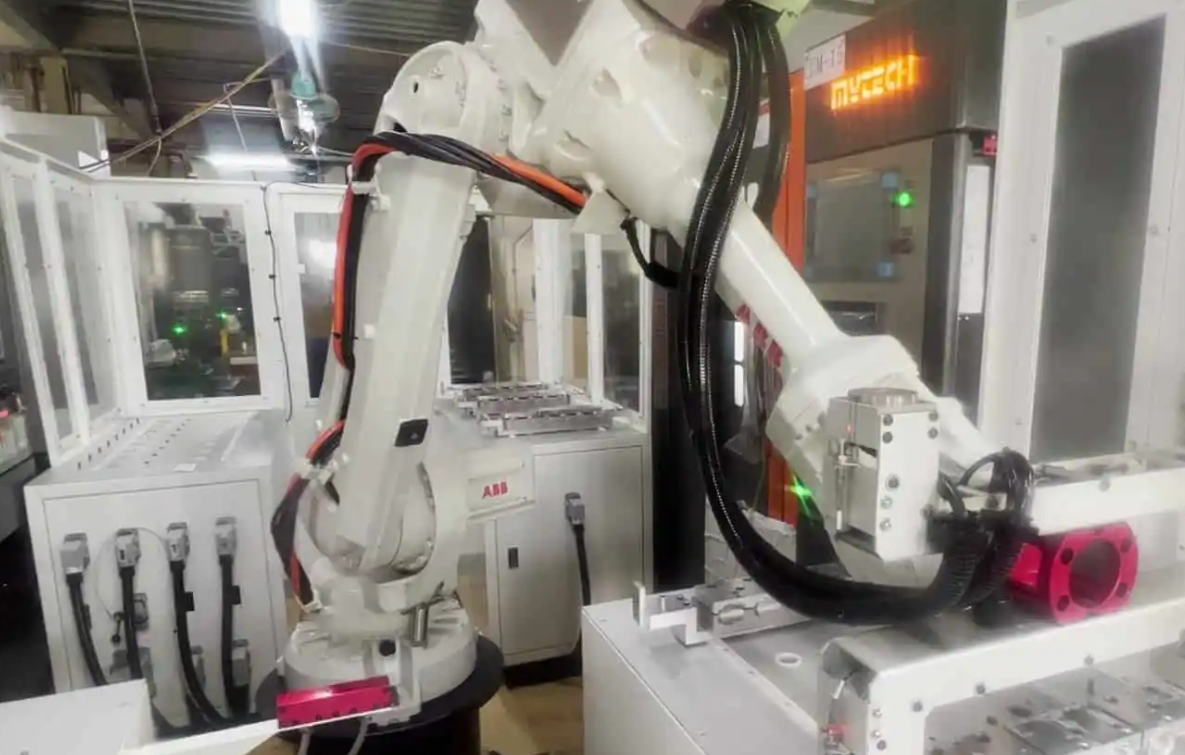

2️⃣ Robotic Automation — Automated Loading/Unloading & Collaborative Machining

- Robot Arm Deployment: Automated loading/unloading, part transfer, multi-machine linking

- Motion Planning: Interference avoidance, path and cycle time optimization

- Sensors & Vision Systems: Workpiece positioning, dimension verification, status detection

- Human-Robot Collaboration: Safety and flexible switching between manual/automatic modes

👉 Role: Eliminates manual bottlenecks, increases CNC machine utilization.

3️⃣ System Integration — Connecting Information and Control Flows

- Control Integration: CNC controller × robotic arm × PLC

- Communication Protocols: EtherCAT, Modbus, PROFINET industrial networks

- MES/ERP Connectivity: Automated scheduling, inventory, and process tracking

- Real-Time Monitoring: Collecting OEE, tool life, and equipment health data

👉 Role: Transforms standalone equipment into interconnected networks for seamless production.

4️⃣ Quality Control — Machining Precision and Reliability

- Automated Inspection: CMM, AOI, laser measurement integrated into the line

- Error Compensation: Correction between CNC machine and robotic arm errors

- SPC (Statistical Process Control): Monitoring machining variation

- Closed-Loop Manufacturing: Machining → Inspection → Correction → Re-machining

👉 Role: Ensures precision and consistency are maintained in automation.

5️⃣ Digital Tools — Driving Smart Manufacturing

- CAD/CAM Integration: Rapidly generating automated machining paths

- Digital Twin: Virtual simulation of CNC and robotic collaboration

- AI/Machine Learning: Tool life prediction, defect recognition, parameter optimization

- Data Analytics: Productivity optimization, yield improvement, energy reduction

👉 Role: Leverages data and AI for continuous process optimization.

✅ Workflow Summary (Text Version):

CNC Machining Expertise → Robotic Automation → System Integration → Quality Control → Digital Tools → Synergy (Smart Manufacturing)

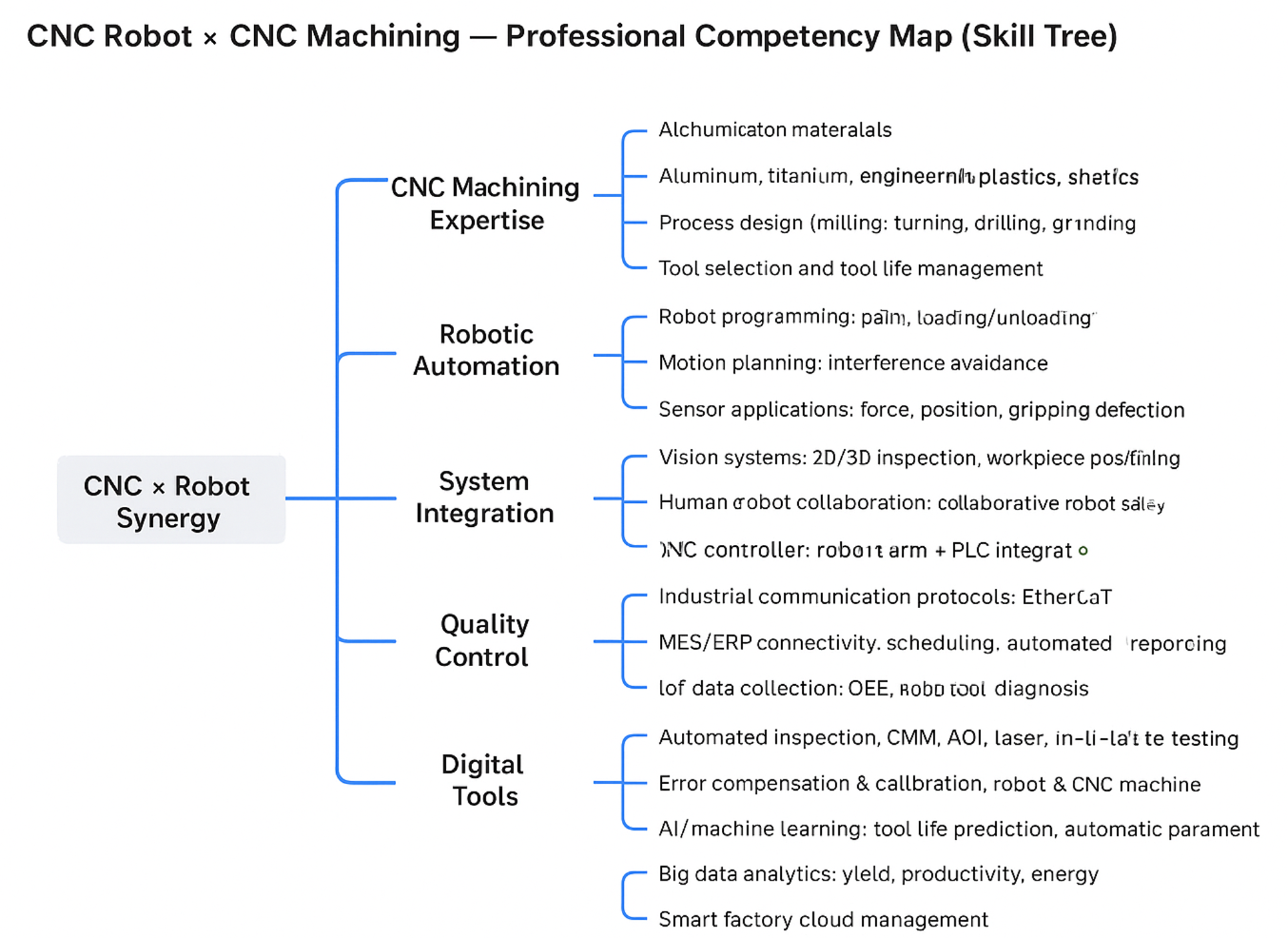

CNC Robot × CNC Machining — Professional Competency Map (Skill Tree)

🌟 Core Goal:

Achieve High Efficiency + High Precision + Automation + Smart Manufacturing with a 1+1 > 2 Synergy

🌐 Core Professional Domains

- CNC Machining Expertise

- Robotic Automation

- System Integration

- Quality Control

- Digital Tools

🌳 Skill Tree Branches

1️⃣ CNC Machining Expertise

- Knowledge of Materials (Aluminum, Titanium, Engineering Plastics, Silicon Carbide…)

- Process Design (Milling / Turning / Drilling / Grinding)

- Tool Selection & Tool Life Management

- Fixture & Workholding Design

- Machining Parameter Optimization

2️⃣ Robotic Automation

- Robot Programming (Path, Loading/Unloading, Pick & Place)

- Motion Planning & Interference Avoidance

- Sensor Applications (Force, Position, Gripping Detection)

- Vision Systems (2D/3D Inspection, Workpiece Positioning)

- Human-Robot Collaboration (Collaborative robot safety applications)

3️⃣ System Integration

- CNC Controller × Robot Arm × PLC Integration

- Industrial Communication Protocols (EtherCAT / Modbus / PROFINET)

- MES / ERP Connectivity (Scheduling, Automated Reporting)

- IoT Data Collection (OEE, Tool Status)

- Real-Time Monitoring & Fault Diagnosis

4️⃣ Quality Control

- Automated Inspection (CMM / AOI / Laser / In-line Testing)

- Error Compensation & Calibration (Robot + CNC machine)

- SPC (Statistical Process Control)

- Closed-Loop Manufacturing (Machining → Inspection → Correction → Re-machining)

- High Reliability & Precision Tracking

5️⃣ Digital Tools

- CAD/CAM Automated Toolpath Generation

- Digital Twin (Virtual CNC × Robot Collaboration)

- AI / Machine Learning (Tool life prediction, automatic parameter adjustment)

- Big Data Analytics (Yield, Productivity, Energy)

- Smart Factory Cloud Management

📈 Suggested Skill Tree Visualization

- Core (Center): “CNC × Robot Synergy”

- First-Level Branches: Five Professional Domains (Machining / Automation / Integration / Quality / Digitalization)

- Second-Level Branches: Professional skills per domain (e.g., Tool Selection, Vision Systems, MES Integration, AI)

- Third-Level Branches: Advanced Applications (Smart Manufacturing, Self-learning Processes, Automated Scheduling)

CNCmachining #RoboticsAutomation #SystemIntegration #QualityControl #DigitalTools #SmartManufacturing #SynergyEffect #1plus1greaterthan2 #MultiAxisMachining #AutomaticLoadingUnloading #CollaborativeMachining #ControlIntegration #IndustrialCommunication #MES #ERP #RealTimeMonitoring #CMM #AOI #LaserMeasurement #ErrorCompensation #SPC #ClosedLoopProcess #CADCAM #DigitalTwin #AI #MachineLearning #BigDataAnalytics #CloudManagement #SmartFactory #ToolManagement #FixtureDesign #WorkpieceMaterials #ProcessDesign #MotionPlanning #VisionSystem #HumanRobotCollaboration #IoT #ProductivityOptimization #YieldImprovement #EnergyReduction

Explains how to integrate FANUC robots with CNC controllers, including tools like Robot ON-SITE, Robot G-CODE, and Robot CONNECT.

➡️ https://www.fanucamerica.com/products/cnc/robot-and-cnc-integration

詠翊科技有限公司

location_on 42756 台灣台中市潭子區大豐路一段188-9號

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com