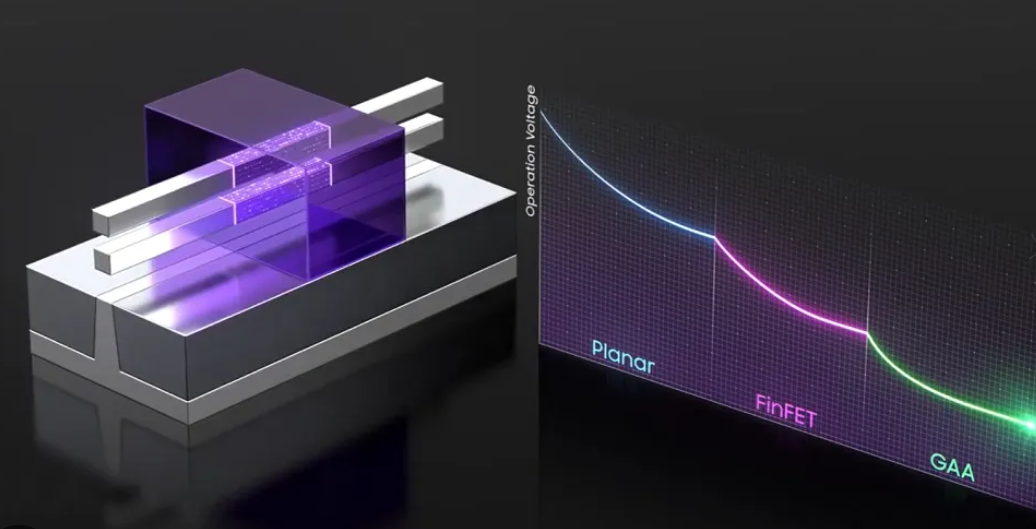

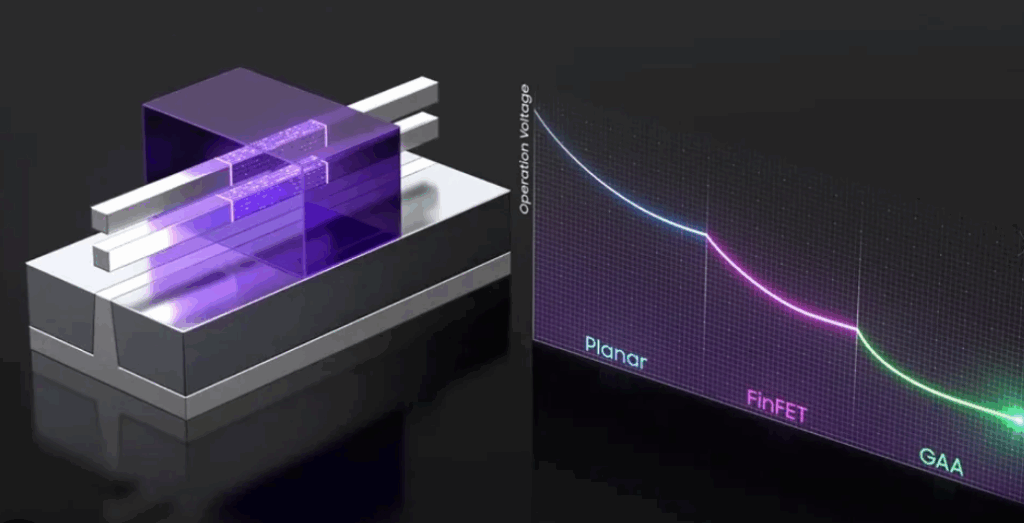

Basic Concepts: What is GAA?

GAA (Gate-All-Around) is a next-generation field-effect transistor (FET) architecture, the successor to FinFET (Fin Field-Effect Transistor).

In FinFET, the gate wraps around three sides of the transistor channel;

In GAA, the gate completely surrounds the channel, providing stronger control, suppressing leakage, and improving performance.

Currently, the mainstream implementations of GAA are nanosheet or nanowire structures.

The core of GAA lies in multi-layer stacked channels and gate-around formation.

The manufacturing process mainly includes the following steps:

🧩 1️⃣ Superlattice Stacking

Multiple Si (silicon) and SiGe (silicon germanium) layers are grown alternately on a silicon substrate. For example: Si / SiGe / Si / SiGe / Si …

The Si layer will serve as the channel, while the SiGe layer will be etched away later to “release” the nanosheet.

📘 Key Technology: Epitaxy

This is used to precisely control the thickness (~5nm) and stress of silicon/silicon germanium layers on the wafer.

🌐 Relationship Between GAA (Gate-All-Around) Transistor and CNC Precision Machining

Although GAA (Gate-All-Around) transistors belong to the nanometer-scale semiconductor fabrication domain, and CNC machining operates in the millimeter-to-micrometer precision manufacturing domain, the two are closely connected.

In reality, CNC plays a critical supporting role in the manufacturing of GAA fabrication equipment and materials engineering components.

🧩 I. Overall Relationship Map

GAA Process → Semiconductor Equipment → Precision Components → CNC Machining

In short, GAA chips cannot be made directly with CNC,

but the equipment, fixtures, and material modules required for GAA fabrication are all realized through CNC precision manufacturing.

🔹 II. Hierarchical Relationship Explanation

1️⃣ Precision Components in Semiconductor Equipment Are CNC-Made

Key GAA process equipment includes the following:

| Equipment Type | Key Function | CNC-Related Components |

|---|---|---|

| ALD / CVD Deposition Systems | Nanometer-scale thin film deposition | Vacuum chambers, gas flow plates, temperature-controlled chucks |

| Etching (Etcher) Systems | Nanostructure etching | Ceramic insulation rings, cathode plates, support rings, electrode bases |

| CMP Planarization Systems | Nanosurface finishing | Polishing heads, platen frames, slurry distribution structures |

| Metrology / Inspection Tools | Nanoscale alignment and surface analysis | Scanning stages, optical housings, vibration isolation frames |

👉 Nearly all of these structural components are produced by CNC precision machining, followed by grinding and surface finishing.

2️⃣ GAA Fabrication Requires Extreme Precision — Equipment Relies Heavily on CNC

Since GAA transistors involve nanometer-scale structures (e.g., nanosheets only ~5 nm thick),

the corresponding equipment must achieve:

- Geometric tolerance: ±2 μm or better

- Surface roughness: Ra ≤ 0.1 μm

- Thermal stability: ±0.001°C

➡️ Therefore, the metallic and ceramic components in these systems must be made using:

- 5-axis CNC machining for complex cavities and fluid channels

- Ultra-precision grinding / mirror polishing

- Coordinate measuring machines (CMM) for geometric verification

3️⃣ CNC Materials Are Directly Linked to GAA Equipment Material Engineering

| CNC Material | GAA Equipment Application | Key Material Properties |

|---|---|---|

| Aluminum Alloys (Al6061, Al7075) | Vacuum chambers, stage frames | Lightweight, high thermal conductivity |

| Titanium Alloy (Ti-6Al-4V) | Electrodes, support rings | Corrosion resistance, high-temperature stability |

| Stainless Steel (SUS316L, 304) | Gas piping, frame structures | Chemical resistance |

| Tungsten, Molybdenum, Tantalum | Electrodes, plasma components | High melting point, low vapor pressure |

| Ceramics (Al₂O₃, SiC, AlN) | Insulating parts, chamber liners | High corrosion resistance, insulation, thermal stability |

These materials are processed by high-speed CNC cutting, ultrasonic machining, or laser-assisted milling.

4️⃣ CNC’s Role in GAA Equipment Development Phase

During the R&D and prototyping stage of GAA equipment, CNC suppliers are responsible for:

- Rapid prototyping of chambers and mechanical structures

- Design optimization of gas channels and flow paths

- Supporting vacuum and thermal simulations with quick design iterations

➡️ These prototype components are custom-built, time-sensitive, and high-precision,

relying on advanced CNC centers integrated with automation and metrology systems.

5️⃣ GAA Evolution Drives CNC Precision Advancements

| GAA Technology Challenge | CNC Manufacturing Response |

|---|---|

| High thermal stability requirement | Temperature-controlled machining environment, low-expansion materials |

| Micro gas channels and tiny cavities | Micro-milling, Micro-EDM |

| Ceramic-metal hybrid assemblies | Ultrasonic or laser-assisted cutting |

| Extreme surface flatness | Mirror polishing, AFM-based surface inspection |

➡️ As GAA nodes scale down, CNC technologies evolve to meet nanoscale-level stability and precision.

🔹 III. Real-World Application Examples

| Domain | CNC Product | GAA-Related Process |

|---|---|---|

| Vacuum chamber manufacturers (e.g., GlobalWafers, AIDC supply chain) | CNC-machined aluminum chambers | Used in ALD / CVD deposition |

| Ceramic component suppliers (e.g., Kyocera, CoorsTek) | CNC-ground Al₂O₃, SiC components | Used in etching and CMP systems |

| Semiconductor equipment makers (e.g., Applied Materials, Lam Research, Tokyo Electron) | CNC-machined precision fixtures and assemblies | Core components for GAA fabrication |

🔹 IV. Summary

| Level | Key Relationship |

|---|---|

| Process Level (GAA) | Nanometer-scale materials and transistor structures |

| Equipment Level | ALD / CVD / Etch / CMP / Metrology systems |

| Mechanical Level | Chambers, jigs, bases, flow modules |

| CNC Manufacturing Level | Precision machining of metal and ceramic components |

👉 CNC precision machining is the foundation that enables GAA process equipment to achieve nanoscale control.

Without high-precision CNC capabilities, stable mass production of GAA transistors would be impossible.

#GAA Transistor Process and CNC Precision Machining #Semiconductor Equipment Component Processing #GAA Process Materials Engineering #Precision Machining Supports Advanced Processes

#Semiconductor Manufacturing and Machining Integration #GAA Process CNC Technology Map

#Precision CNC Machining #5-Axis Machining #Vacuum Chamber Machining #Ceramic Component Grinding #High-Precision Fixtures #Gas Flow Path Machining #Temperature Control Base #Micro Milling #Ultrasonic Machining #Electrical Discharge Machining #Mirror Polishing #Geometry Measurement

Yong Yi Technology Co., Ltd.

location_on No. 188-9, Section 1, Dafeng Road, Tanzi District, Taichung City, Taiwan 42756

call +886-4-25341382

ring_volume

+886-4-25341847

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com