CNC precision components × Stainless steel machining × OEM/ODM manufacturing available for export

📌 1. Preparation Before Stainless Steel Machining

1. Material Selection and Verification

Common stainless steel grades processed at Yong-Yi Technology include SUS303, SUS304, SUS316, SUS420, SUS440 (with varying hardness and corrosion resistance).

Material selection should be based on application requirements (structural strength, corrosion resistance, precision requirements) to determine the most suitable grade.

2. Technical Evaluation and Process Planning

- Review part drawings and specified tolerances and surface roughness (Ra).

- Select the most appropriate CNC machine (3-axis, 4-axis, 5-axis) and tool types.

- Consider stainless steel’s tendency for high heat generation and work hardening during cutting, and determine proper cutting parameters (feed rate, spindle speed, cutting depth).

📌 2. CNC Machining Steps and Key Technical Points

1. Loading and Fixturing

Clamp stainless steel blanks (bar or billet) on the CNC machine using fixtures or vices to ensure rigidity and prevent vibration. This forms the foundation for high-precision machining.

2. Roughing

Purpose:

- Rapidly remove bulk material and approach the desired shape.

- Reduce cutting load for subsequent finishing.

Key Practices:

- Use heat-resistant, high-rigidity tools (e.g., carbide cutters).

- Apply lower spindle speeds but higher feed rates to prevent overheating.

- Use high-pressure coolant to maintain cutting temperature and reduce tool wear.

Stainless steel’s toughness and poor thermal conductivity can lead to rapid tool wear; thus, tool life management and cooling are critical.

3. Semi-Finishing

Purpose:

- Remove residual material from roughing.

- Establish a stable reference surface for final finishing.

Characteristics:

- Cutting parameters are milder than roughing to reduce deformation and residual stress.

- Moderate cutting depth and feed rate improve dimensional control.

- Multiple tools and repositioning may be applied for multi-face or corner features to ensure final tolerances.

4. Finishing

Purpose:

- Achieve drawing tolerances and surface roughness (Ra) specifications.

Key Points:

- Use high-precision tools with higher spindle speeds and lower feed rates.

- Reduce cutting forces to improve dimensional stability.

- Multi-face or complex-angle parts may be completed using 4-axis or 5-axis machining to minimize re-clamping errors.

- Controlling tool wear and machine rigidity is critical, especially as stainless steel is more abrasive to cutting tools.

📌 3. Surface Treatment (Post-Processing)

After machining, Yong-Yi Technology provides additional surface treatments for improved functionality or aesthetics:

1. Grinding – Achieves smoother surfaces and tighter dimensional accuracy.

2. Electropolishing – Stainless steel parts are immersed in electrolyte; micro-peaks are removed to improve smoothness, corrosion resistance, and appearance. Ideal for medical and semiconductor components.

3. Heat Treatment / Other Surface Finishes – Improves hardness and toughness; other treatments such as sandblasting or blackening are applied based on functional or aesthetic needs.

📌 4. Measurement and Quality Control

After machining and surface treatment, a complete quality control process is performed:

- Use CMM (coordinate measuring machine) to measure critical dimensions.

- Check flatness, straightness, concentricity, thread accuracy, etc.

- Ensure all parts meet customer tolerances and standards.

Yong-Yi Technology emphasizes full-process integration: material → machining → surface treatment → measurement → assembly and shipment.

📌 5. Key Process Control Considerations (Stainless Steel Specifics)

Compared with aluminum or carbon steel, stainless steel presents challenges:

- High cutting heat → requires proper cooling and optimized parameters.

- High toughness and work hardening → requires precise feed and tool selection.

- High surface requirements → finishing and post-treatment must be closely coordinated.

Yong-Yi Technology uses high-rigidity CNC machines with advanced tooling and cooling management to address these challenges.

📌 6. Common Applications

Stainless steel CNC components are commonly used in:

- Semiconductor equipment parts

- Medical devices

- Automation machinery structural components

- Optical and precision tooling

Yong-Yi Technology emphasizes high precision and consistency across these industries.

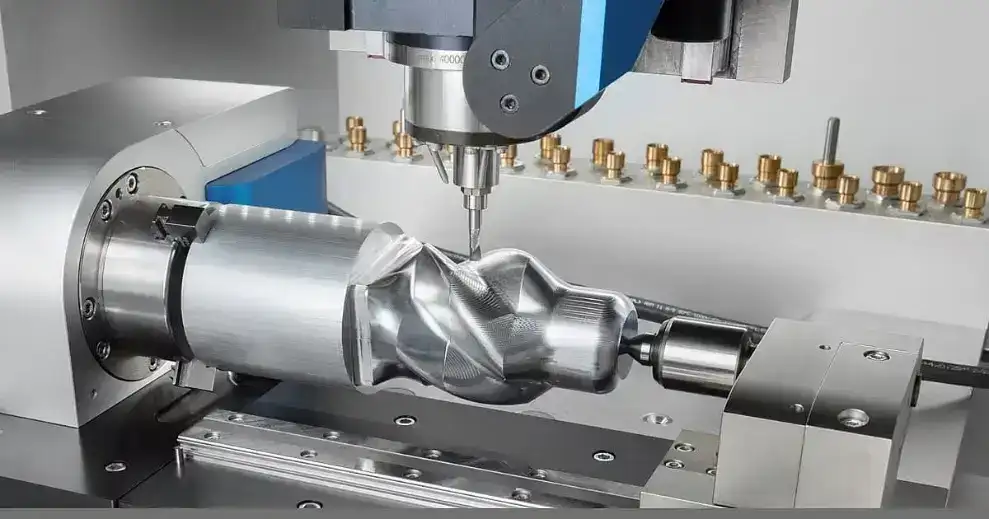

Actual Process & Equipment Images of Yong-Yi Technology

(3-Axis, 4-Axis, and 5-Axis CNC Machining Centers)

Below is a structured introduction to Yong-Yi Technology’s CNC machining equipment and real manufacturing process visuals, covering 3-axis, 4-axis, and 5-axis machining centers, including both actual machines and process illustrations for reference.

🛠️ CNC Machining Equipment & Facilities at Yong-Yi Technology

The following images represent actual CNC machining centers and workshop environments used by Yong-Yi Technology, illustrating the company’s advanced manufacturing capabilities:

Equipment & Process Image Descriptions:

- Vertical CNC Machining Centers at Yong-Yi Technology

Actual machine tools used for 3-axis, 4-axis, and 5-axis precision machining, showing the machine structure and rigidity. - Additional CNC Machining Centers (Representative Models)

Examples of high-precision CNC machines suitable for complex metal component manufacturing. - In-house Automated Machining Environment

Displays the real production floor with machine tools, tool magazines, and automation integration, reflecting stable and repeatable mass-production capability. - 5-Axis CNC Machining in Operation

Demonstrates real or representative cutting scenarios where the tool and workpiece move simultaneously at complex angles, enabling high-precision multi-surface machining.

📌 CNC Machining Axis Configuration & Motion Illustrations (Conceptual)

To better understand the differences between machining configurations, the following conceptual illustrations explain axis movement and cutting flexibility:

- Multi-Axis CNC Machining Overview (3-Axis / 4-Axis / 5-Axis)

Illustrates the motion principles and tool orientation possibilities for different axis configurations. - Axis Comparison Diagrams

Shows the coordinate systems and rotational axes (A, B, C) used in 3-axis, 4-axis, and 5-axis CNC machining. - 4-Axis Machining in Practice

Example of indexed or continuous 4-axis machining, commonly used for cylindrical or multi-face components. - 5-Axis Complex Surface Machining

Demonstrates simultaneous tool and workpiece movement, ideal for high-precision and geometrically complex parts.

🧩 Additional Notes & Technical Highlights

📌 Yong-Yi Technology’s official website provides detailed information on CNC machining capabilities, including 5-axis and 4-axis machining, along with downloadable brochures and real production case studies.

📌 5-Axis CNC machining allows simultaneous movement along X, Y, Z axes plus two rotational axes (A/C or B/C), enabling complete multi-face machining in a single setup. This significantly improves accuracy, reduces setup time, and enhances surface quality.

📌 Most high-precision CNC machines are integrated with automatic tool changers (ATC) and automation systems, ensuring high productivity, consistency, and stable quality for export-oriented manufacturing.

Yong Yi Technology Co., Ltd.

Location: No. 188-9, Section 1, Dafeng Road, Tanzih District, Taichung City, Taiwan 42756, China

Call: +886-4-25341382

Ring Volume: +886-4-25341847

Email: yongyi-sales@umail.hinet.net

Email: justinwu6767@gmail.com