What is “Electropolishing” | What is “Electropolishing Principle” | What is Stainless Steel Electropolishing | Surface Treatment Anti-Corrosion Technology

1. What is Electropolishing in the CNC Industry?

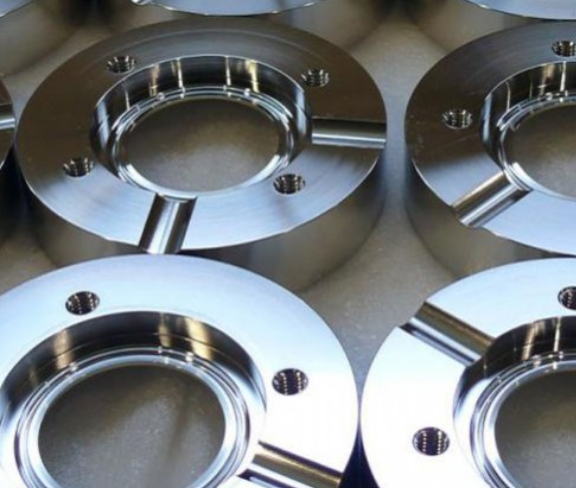

Electropolishing is a surface finishing technique widely used in the CNC industry, especially for components that require high precision, cleanliness, and corrosion resistance. It is an electrochemical process that removes a thin layer of metal from the surface of a workpiece to improve its smoothness and shine.

🔧 What is Electropolishing?

Electropolishing is a process where a metal part is immersed in an electrolyte solution and connected as the anode in a direct current (DC) circuit. When current is applied, the surface peaks (microscopic high points) dissolve faster than valleys, creating a microscopically smooth and bright surface.

✅ Applications of Electropolishing in CNC

| Industry | Common Applications |

|---|---|

| Medical | Surgical tools, implants, stents |

| Semiconductor | Gas pipelines, vacuum chambers |

| Food & Pharmaceutical | Stainless steel tanks, filters |

| Aerospace | Precision parts, tubing |

| High-end electronics | Decorative stainless steel covers |

⚙️ Key Benefits of Electropolishing

- Improves surface smoothness and eliminates micro-burrs

- Enhances corrosion resistance by forming a stable passive layer

- Improves cleanliness – ideal for sterile environments

- Reduces friction and particle adhesion

- Enhances aesthetic appeal with a mirror-like finish

🧪 General Electropolishing Process

- Pre-treatment: Degreasing, acid cleaning to remove oxides and oils

- Electropolishing: Using an electrolyte (commonly a mix of phosphoric and sulfuric acid), the workpiece is processed with low voltage DC power

- Post-treatment: Neutralization, thorough rinsing, drying

2. Electropolishing for Stainless Steel

Electropolishing for stainless steel is an advanced surface treatment process that selectively removes surface material to enhance corrosion resistance, smoothness, and overall performance. It is widely used in high-precision industries such as medical, food processing, semiconductor, and pharmaceuticals.

🔍 Why Electropolish Stainless Steel?

Stainless steel naturally forms a passive chromium oxide layer. Electropolishing enhances this layer, making the material even more resistant to oxidation, chemical corrosion, and pitting. It also removes embedded contaminants and machining residues.

⚙️ Advantages for Stainless Steel

| Feature | Description |

|---|---|

| Mirror-like finish | Improves appearance and cleanliness |

| Deburring | Removes micro-burrs and machining marks |

| Micro-smoothing | Reduces surface roughness, ideal for fluid flow |

| Enhanced passivation | Improves corrosion resistance |

| Biocompatibility | Suitable for medical applications |

🏭 Common Grades for Electropolishing

- 304 – General use

- 316/316L – High corrosion resistance for medical/food use

- 430 – Decorative, lower corrosion resistance

- Duplex 2205 – Strong and chloride-resistant

⚙️ Electropolishing vs Mechanical Polishing

| Comparison | Electropolishing | Mechanical Polishing |

|---|---|---|

| Surface | Uniform, micro-smooth | May retain scratches |

| Cleanliness | High – no abrasives used | May retain compounds/oils |

| Inner surfaces | Effective in small gaps/tubes | Limited accessibility |

| Scalability | Automated, repeatable | Manual variability |

3. What is Corrosion-Resistant Surface Treatment?

Corrosion-resistant surface treatment refers to a range of technologies used to enhance a material’s resistance to rust, oxidation, acid/alkali exposure, and environmental degradation. It is essential for extending product life and maintaining structural integrity in industries such as CNC machining, aerospace, automotive, medical, and electronics.

🔧 Why Apply Surface Treatments?

Metals exposed to air, moisture, or chemicals will naturally corrode. Surface treatments form protective layers that block corrosive agents and minimize wear.

🛡️ Common Corrosion-Resistant Techniques

| Technique | Description | Suitable Materials |

|---|---|---|

| Electropolishing | Micro-removal of surface for smoothness and passivity | Stainless steel, titanium |

| Anodizing | Creates oxide layer on aluminum | Aluminum, titanium |

| Electroplating | Adds protective metal layer (nickel, zinc, etc.) | Steel, copper |

| Electroless Plating | Chemical deposition, uniform thickness | Steel, plastics |

| PVD/CVD Coating | High-hardness vacuum films | High-performance parts |

| Conversion Coating | Chemical surface conversion (e.g., phosphating) | Steel, aluminum |

| Spray Coating | Physical coating of anti-corrosion materials | All substrates |

🧪 Types of Corrosion it Prevents

- Atmospheric corrosion – from oxygen and moisture

- Saltwater corrosion – ideal for marine environments

- Chemical corrosion – acids, alkalis, solvents

- Crevice corrosion – tight spaces and welds

- Stress corrosion cracking – under tension and corrosive conditions

🏭 Industries That Rely on Corrosion-Resistant Treatments

| Industry | Treatment Focus |

|---|---|

| Medical Devices | Cleanability, biocompatibility |

| Food/Pharma | Sanitation and durability |

| Aerospace/Automotive | Long-term resistance and weight saving |

| Semiconductors | Cleanrooms and chemical resistance |

| Mold and Mechanical Parts | Wear and corrosion protection |

CNC machining #CNC machining #Precision machining #Positioning accuracy #Machining accuracy #CNC machine tool #Five-axis machining #Precision parts machining #Automated machining technology #CNC machine accuracy

Loading and unloading machine slide rail #AI automatic stacking robot arm

YongYiTech #Automated Special Machine Manufacturing #Automated Arm Handling and Loading #Automated Testing and Assembly

Robot suction cup gripper series #CNC precision components manufacturing #Semiconductor automation components supply #Stainless steel aluminum alloy carbon steel copper alloy

Engineering plastics #Sheet metal welding group #Ceramic quartz processing #Customized fixture design, manufacturing and development #Customer assembly service

sliding stage fine adjustment stage system #digital microscope #aluminum extrusion trolley #Japanese NPM series products

semiconductor components #automation equipment components #CNC processing #robotic arm loading and unloading #automatic loading and unloading equipment #smart manufacturing #automated production line #smart factory #automation equipment

- cnc machining #cnc precision machining #semiconductor components #automation equipment #precision components #robot arm #stainless steel machining #engineering plastics #ceramic machining

Yongyi Technology