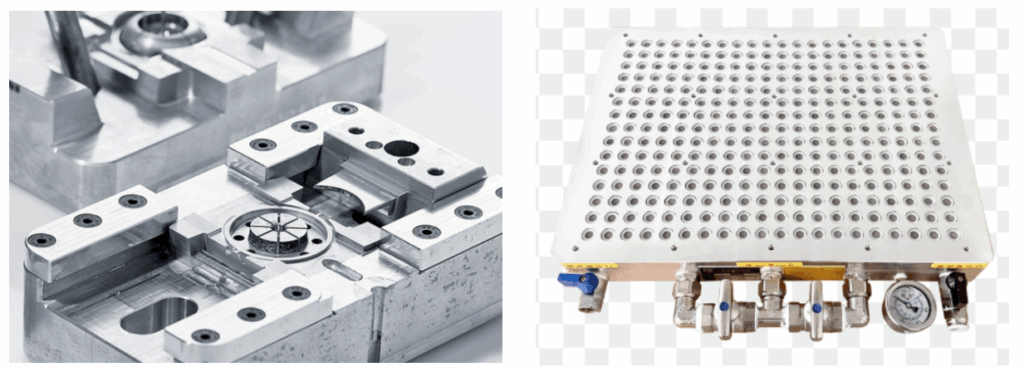

Medical parts’ porous moulds and liquid silicone rubber (LSR) moulds require extremely high standards in CNC manufacturing, due to their precision, surface quality, and complex structures. The main required technologies are as follows:

🔧 CNC Technologies for Porous Moulds

- High-precision micro-machining: Porous structures may have micron-level hole sizes, requiring micro-tools or EDM assistance.

- High-speed milling: Reduces tool load, improves surface quality, and avoids burrs on hole walls.

- 5-axis CNC machining: Enables multi-angle cutting of complex porous geometries, avoiding errors from multiple setups.

- EDM / Micro-EDM: Suitable for tiny deep holes and irregular shapes where conventional tools cannot reach.

- Polishing and surface finishing: Ensures smooth hole walls to prevent residue in medical applications.

🔧 CNC Technologies for LSR Moulds

- Precision cavity machining: Achieve ultra-high surface finish (Ra < 0.2 μm) to ensure smooth LSR moulding surfaces.

- Thermal control features: Accurate machining of heating/cooling channels for temperature regulation.

- Hard steel machining: Capable of hard milling stainless steel or hardened steels.

- 5-axis and deep cavity machining: Suitable for complex curved surfaces and deep cavities without interference.

- Mould alignment accuracy: Achieve micron-level mould fitting to prevent silicone leakage.

一、整體製程流程 | Overall Process Flow (Recommended)

Design Stage (DFM): Confirm hole diameter, tolerance, depth/aspect ratio, venting, and internal surface accessibility.

Rough Machining (conventional milling): Remove most of the stock material.

Micro-milling: Machine fine geometries, sharp corners, and cavity details.

Micro-hole / Deep-hole EDM (hole-drill EDM / micro-EDM): Used when hole diameters are extremely small or materials are too hard.

Deburring & Internal Finishing: If necessary, apply AFM or ultrasonic polishing.

Precision Polishing: Hand polishing, diamond film, ultrasonic, electro-polishing, or mirror-EDM texturing to achieve required Ra.

Inspection: Optical profilometer, white light interferometry, CMM, or microscope measurement.

Cleaning: DI-water rinsing, drying, and packaging (medical parts require cleanroom/no oil).

二、微細銑削(Micro-milling) | Micro-milling

Principle & Application

Uses ultra-small diameter end mills to directly cut micro features and cavities. Suitable for high shape freedom and high surface quality when hole size is within tool capability.

Tools & Equipment

- Micro end mills: 0.05–3 mm, typically ultra-fine grain carbide.

- High-speed spindle: tens of thousands RPM to maintain cutting speed.

- High-rigidity machine, low-vibration fixtures, minimized tool overhang.

- High-precision holders/chucks for minimal runout and dimensional stability.

Machining Strategy / Parameters

- Small depth of cut, shallow step-over, multiple roughing–semi-finishing–finishing passes.

- High feed per tooth with trochoidal paths and climb milling.

- Cooling/lubrication: MQL or light coolant, avoid tool vibration.

Surface Quality & Limits

- Achievable sub-micron Ra, but affected by runout and tool wear.

- For <0.08–0.1 mm diameters or high aspect ratios, micro-EDM is preferred.

三、微細 EDM(Micro-EDM) | Micro Electrical Discharge Machining

Principle & Application

Removes material through electrical discharges. Suitable for ultra-small deep holes, non-standard shapes, or features inaccessible to cutting tools. Works only with conductive materials.

Tools & Equipment

- Micro-electrodes: copper/tungsten, as small as 10–20 μm diameter.

- Precision servo control to maintain discharge gap.

- Stable power supply for controlled pulse energy.

- Rigid machine structure to ensure discharge stability.

Machining Strategy / Parameters

- Low-energy pulses to remove material at micron scale.

- Slow feed with segmented machining to avoid short circuits.

- Ideal for high aspect ratio holes, fine micro-features, and medical implant moulds.

Surface Quality & Limits

- Achievable Ra <0.1 μm, burr-free.

- Lower efficiency than milling, restricted to conductive materials.

四、拋光與表面處理 | Polishing & Surface Finishing

Purpose

Remove burrs, eliminate EDM recast, reduce Ra, and ensure fluid/biocompatibility—especially critical for medical parts.

Common Methods

- Manual/Mechanical Polishing: oil stones, diamond wheels, felt wheels.

- Mirror EDM / mirror-EDM texturing.

- Ultrasonic Polishing: effective for deep cavities and micro holes.

- Abrasive Flow Machining (AFM / Extrude Honing): high-viscosity abrasive fluid removes EDM recast uniformly.

- Electrochemical Polishing / Chemical Etching: remove micron-level surface layer and stress concentration.

Surface Roughness Targets

- High-grade LSR molds: Ra ≤ 0.2 μm.

- Standard molds: Ra 0.4–1.0 μm.

五、檢測與量測 | Metrology

Common Instruments / Methods

- White-light interferometer / 3D optical profiler: non-contact measurement of micron/sub-micron surface roughness and topology.

- Optical microscope / vision measurement system: magnified inspection of hole openings, diameters, and defects.

- CMM (contact measurement): measure overall geometry and tolerances; limited for micro holes or thin-walled parts.

- Specialized micro-probes / non-contact fiber probes: scan inner diameters of tiny holes.

Practical Notes

- Micro-holes and internal surfaces require 100–400x magnification or interferometer checks for Ra and residual particles.

- Include measurement steps in process validation (IQ/OQ/PQ), especially critical for medical parts.

六、常見問題與實務建議 | Common Issues & Practical

| Issue | Possible Cause | Solution / Recommendation |

|---|---|---|

| Tool breakage / chipping | Excessive tool overhang, cutting depth too large, insufficient rigidity | Reduce tool overhang, lower cutting depth, use shorter/more rigid holders, increase spindle rigidity |

| Vibration / chatter affecting surface | Fixture rigidity insufficient, unbalanced tool | Improve fixture rigidity, balance tools, use vibration-avoidance tool paths, reduce cutting parameters |

| EDM recast / white layer | Rough discharge or improper parameters | Use fine discharge parameters, follow with AFM / ultrasonic / chemical polishing |

| Internal holes cannot be polished | Poor accessibility for deep/narrow holes | Use AFM, ultrasonic fluid polishing, or design demountable mold sections |

| Cleaning / residual oil or polishing paste | Inadequate cleaning | Ultrasonic cleaning + DI water rinse + drying / sterilization, establish clean verification procedure |

| Dimensional instability (flash / sealing issues) | Low mold alignment accuracy or poor thermal control | Increase mold alignment precision, control mold temperature, check surface roughness and tolerance |

Practical Recommendations

- Micro-hole ≥0.1 mm with aspect ratio <3–5: use micro-milling; hole <0.08–0.1 mm or high aspect ratio: micro-EDM recommended.

- Surface roughness targets: LSR/mirror areas Ra ≤0.2 μm; standard molds Ra 0.4–1.0 μm.

- Inspection items: hole diameter, position, tolerance, Ra, burrs, EDM recast, cleanliness.

#PorousMould #MicroHoleAccuracy #SurfaceQuality #MicroMilling #MicroEDM #ElectricalDischargeMachining #SmallHoleDrilling #DeepHoleMachining #MouldPolishing #MirrorPolishing #UltrasonicPolishing #AbrasiveFlowMachining #AFM #InternalSurfaceFinishing #MouldInspection #OpticalMeasurement #CMM #MedicalMould #MicrofluidicChips #MedicalConsumables #Implants

-> 工具機產業報告PMC

詠翊科技有限公司

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com