PEEK (Polyether Ether Ketone) and CNC machining industry complete supply chain structure, from raw materials → forming → precision machining → assembly applications → downstream industries, explained step by step:

—

PEEK and CNC Machining Industry — Complete Supply Chain Diagram (Text Version)

① Upstream: Raw Material Supply

● Raw material manufacturers

Produce PEEK resin (such as Victrex, Solvay, Evonik)

Provide PEEK pellets, PEEK rods, PEEK plates, and PEEK tubes

● Material processing plants

Extrude PEEK resin into rods, plates, and films

Provide semi-finished products that can be directly machined by CNC

—

② Midstream: PEEK Forming Processes

Mainly divided into two forms for CNC manufacturers:

A. Forming Processes (providing blanks for CNC)

1. Injection molding

Suitable for mass-produced parts (medical devices, electronic housings).

2. Extrusion

Produces PEEK rods/plates/tubes — the most common raw form for CNC machining.

3. 3D printing (FDM / SLS high-temperature printing)

Used for complex lightweight structures, often combined with CNC secondary machining.

—

③ Midstream: CNC Precision Machining (Core Value)

When PEEK semi-finished products enter CNC machining, they become high-precision components.

Main CNC processes:

CNC Turning (Lathe): pipes, shafts, ring-shaped parts

CNC Milling: precision components, cavities, mechanical assemblies

5-axis machining: complex medical and aerospace parts

Secondary processes: fine grinding, polishing, deburring

Advantages of CNC machining PEEK

Accuracy up to ±0.01 mm

Heat resistance to 250°C

High wear resistance, high strength, chemical resistance

Can replace metals (titanium, aluminum) to reduce weight

—

④ Downstream: Application Industries

1. Medical Industry

Interbody cages

Medical catheter components

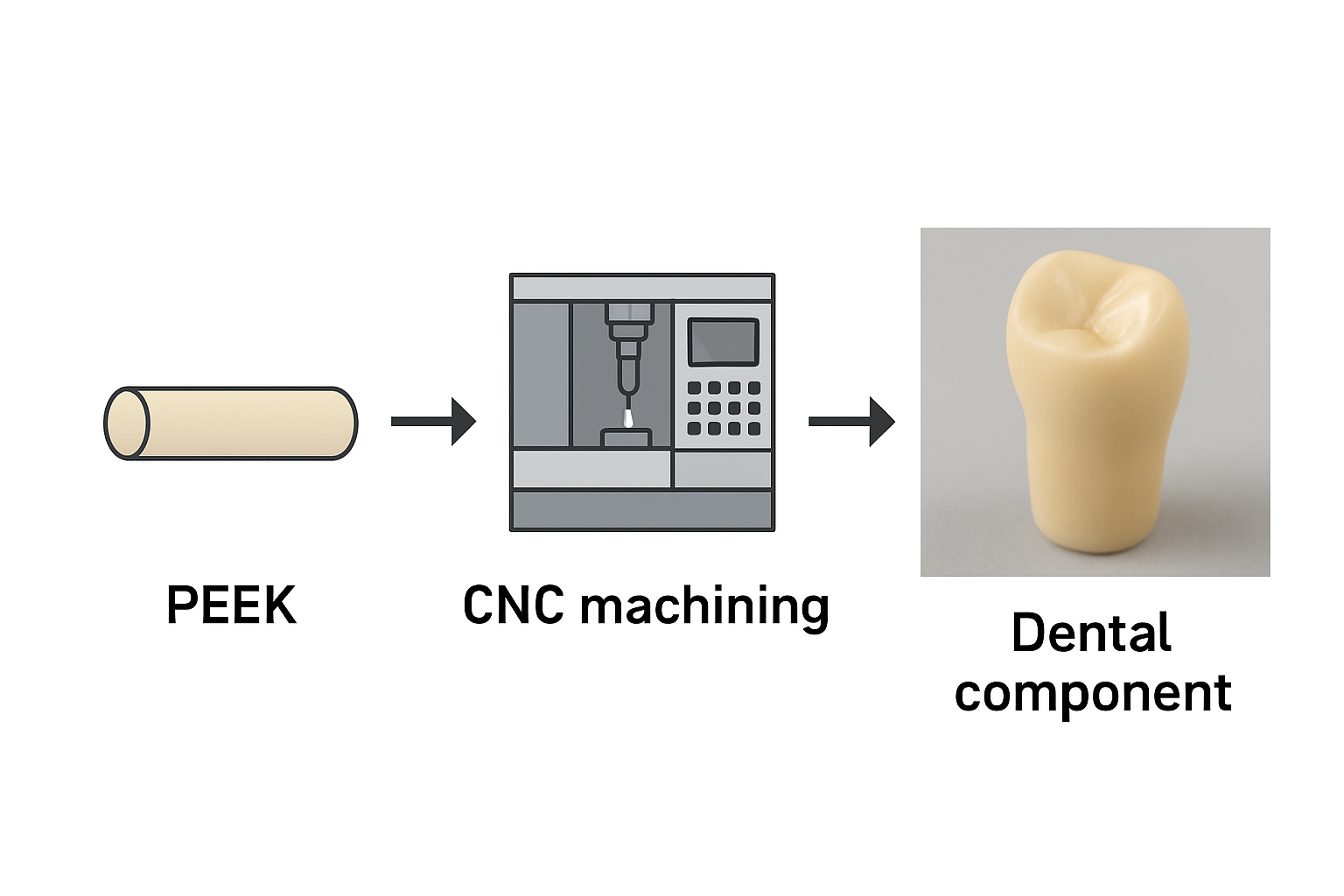

Dental treatment parts

Robotic surgical arm components

2. Aerospace & Defense

Lightweight structures

Insulation holders, mounts

Heat-resistant / pressure-resistant parts

3. Semiconductor Equipment

Chemically resistant components

Common in Taiwan: fixtures, positioning blocks, sliders, thermal insulation pads

4. Precision Industry & Automation

High-wear sliding components

Robotic joint sleeves

Connectors, pressure-resistant fittings

PEEK × CNC Machining Industry Chain (Summary)

Raw material manufacturers → PEEK material suppliers (plates/rods)

→ Forming processes (injection/extrusion/3D printing)

→ CNC high-precision machining (turning/milling/5-axis)

→ Surface treatment / QC

→ Assembly / equipment manufacturers

→ Medical / semiconductor / aerospace / industrial automation

How PEEK Works in Medical Applications and How It Integrates with CNC Machining

✅ The Role of PEEK in Medical and Healthcare Applications

PEEK (Polyether Ether Ketone) is a high-performance engineering polymer with:

- High strength and low weight

- High temperature resistance (steam-sterilizable)

- Excellent biocompatibility (implant-grade)

- Chemical and fatigue resistance

- Radiolucency under X-ray and CT (no metal artifacts)

Common medical applications include:

- Spinal fusion cages

- Dental implant abutments

- Surgical tools and disposable guides

- Joint replacement components

- Orthopedic fixation plates

🌟 Manufacturing Workflow of PEEK Medical Devices

Medical components require high precision, surface quality, and durability.

PEEK machining differs from metals and demands advanced control.

🏭 CNC + PEEK Integration Process

1️⃣ Raw Material Preparation

- PEEK rods or sheets

- Medical-grade or implant-grade PEEK (e.g., Invibio)

2️⃣ CNC Machine Setup (Core Process)

Machining PEEK focuses on high speed, low cutting force, and thermal control.

Key considerations:

- Tools: Sharp carbide end mills and drills

- Spindle speed: 10,000–24,000 rpm

- Feed rate: High feed to prevent melting

- Cooling: Air cooling or MQL (avoid emulsions due to moisture absorption)

- Workholding: Soft jaws to prevent deformation

3️⃣ CNC Machining of Medical Components

Example – PEEK spinal cage manufacturing:

- Rough milling

- Contour shaping

- Slotting and hole machining

- Surface texturing for osseointegration

- Fine finishing

4️⃣ Inspection & Quality Control

- CMM dimensional measurement

- Surface roughness testing (Ra 1.6–0.8 μm)

- Radiolucency verification

- Strength & fatigue tests

5️⃣ Cleaning & Sterilization

PEEK supports:

- Autoclave

- Gamma radiation

- EtO sterilization

6️⃣ Assembly, Packaging & Certification

Depends on application:

- ISO 13485

- USP Class VI

- FDA 510(k) / CE approval

🔧 Why CNC Machining Is Ideal for PEEK in Medical Devices

- High precision (±0.01 mm)

- No metal-like internal stress during machining

- Ability to create complex 3D structures

- Suitable for small-batch customized medical components

📌 Summary

PEEK’s biocompatibility and mechanical strength make it a leading implant material, while CNC machining provides the precision and flexibility required for advanced medical manufacturing.

#PEEK #CNCmachining #CNCprecisionmachining #SemiconductorComponents #AutomationEquipment #PrecisionParts #RobotArm #StainlessSteelMachining #EngineeringPlastics #CeramicMachining

Yong Yi Technology Co., Ltd.

📍 188-9, Section 1, Dafeng Road, Tanzih District, Taichung City 42756, Taiwan

📞 +886-4-25341382

📞 +886-4-25341847

✉️ yongyi-sales@umail.hinet.net

✉️ justinwu6767@gmail.com