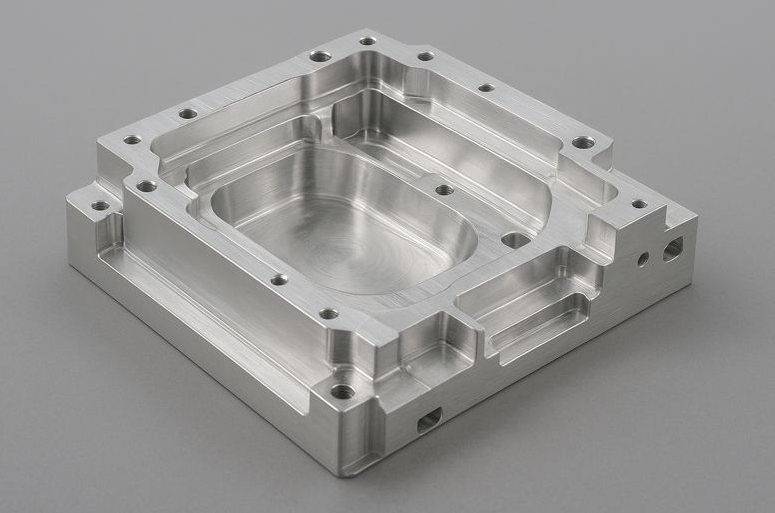

🔬 Semiconductor Equipment Aluminum Parts × 5-Axis Machining Process Analysis

What Are the Five Axes of a 5-Axis Machining Center?

The “five axes” of a 5-axis machining center refer to five degrees of freedom that allow the cutting tool or workpiece to move and rotate simultaneously in different directions. These axes typically include:

✅ Three Basic Linear Axes (Same as a 3-Axis Milling Machine)

- X-axis — Left–right movement

- Y-axis — Front–back movement

- Z-axis — Up–down movement

These three axes control the tool’s position in three-dimensional space.

✅ Two Additional Rotational Axes (A, B, or C)

- A-axis — Rotation around the X-axis

- B-axis — Rotation around the Y-axis

(Sometimes the C-axis—rotation around the Z-axis—is used instead. Most 5-axis machines use two of these rotational axes.)

📌 Common 5-Axis Configurations

Different manufacturers and models use different structures. Common configurations include:

① Trunnion Table (Rotary + Tilting Table)

- A-axis: Table tilts around the X-axis

- B-axis: Table rotates around the Y-axis

➡️ Suitable for large or heavy workpieces

② Tilting Spindle Head

- A-axis: Spindle head tilts around the X-axis

- C-axis: Spindle head rotates around the Z-axis

➡️ Ideal for complex parts requiring high angular flexibility

🛠 What Can a 5-Axis Machine Do?

Compared with traditional 3-axis machining, 5-axis machining provides two additional angular degrees of freedom, enabling:

✔ Machining complex surfaces in a single setup

✔ Reduced workpiece re-clamping

✔ Improved accuracy and productivity

✔ Optimized tool orientation and collision avoidance

1. Role and Characteristics of Aluminum Parts in Semiconductor Equipment

📌 Common Application Components

- Vacuum Chambers

- Wafer Carriers / Chuck Bases

- Frames / Brackets

- Gas Distribution Plates

- Masks, Covers, Heat Dissipation Structures

📌 Why Aluminum Alloys Are Widely Used in Semiconductor Equipment

| Requirement | Aluminum Alloy Advantage |

|---|---|

| High Precision | Easily achieves micron-level machining |

| Lightweight | Reduces equipment inertia |

| Thermal Stability | Rapid heat dissipation |

| Vacuum Compatibility | Low outgassing |

| Corrosion Resistance | Suitable for surface treatment |

2. Common Aluminum Material Grades for Semiconductor Equipment

✅ Specified Grades (Very Important)

- 6061-T6 (Semiconductor Grade)

- 6063 / 6082 (Structural Components)

- MIC-6 / ALCA-5 (Stress-Relieved Plates)

📌 Key Focus for Semiconductor Aluminum Parts:

Not “strength,” but low internal stress + high purity + controlled deformation

3. Key Value of 5-Axis Machining for Semiconductor Aluminum Parts

🔑 Why 5-axis machining is almost always required for semiconductor aluminum parts:

1️⃣ Complex Vacuum Structures

- Multi-surface sealing grooves

- O-ring grooves (high flatness)

- Internal curves and gas channels

2️⃣ Angled / Multi-directional Holes

- Gas inlet holes

- Sensor holes

- Threaded holes at different angles

3️⃣ Single Setup Requirement

- Setup errors = vacuum leakage risk

- 5-axis machining allows multiple surfaces in a single setup

4. 5-Axis Machining Process for Semiconductor Aluminum Parts

1️⃣ Pre-Processing (DFM / DFM+)

- Confirm vacuum surfaces and sealing surfaces

- Define critical surfaces

- Set reference surfaces and clamping directions

- Reserve material for surface treatment compensation

📌 Semiconductor Aluminum Parts: define “surfaces that cannot fail” first

2️⃣ 5-Axis CAM Strategy (Key Points)

- Mainly 3+2 positioning

- 5-axis simultaneous used locally (curved surfaces, chamfers)

- Fixed tool orientation to avoid uneven surfaces

👉 Semiconductor equipment ≠ aerospace aesthetic parts

👉 Stability > fancy tool paths

3️⃣ Fixture Design (Fixture Engineering)

- Custom aluminum fixtures (same material for thermal expansion match)

- Vacuum suction or low-stress clamping

- Protect reference surfaces (no damage allowed)

📌 Most semiconductor aluminum parts require custom fixtures

4️⃣ Rough Machining (Stress Control)

- Material removal in sections

- Symmetrical left-right machining

- Avoid excessive single-sided cutting

Purpose:

Reduce residual stress → prevent deformation

5️⃣ Intermediate Stress Relief (Critical Difference)

- Common for semiconductor-grade parts:

- After rough machining → artificial aging / natural aging

- Then semi-finish and finish machining

📌 This step is absent in general industrial parts

6️⃣ Finish Machining (Vacuum-Grade Standard)

- Sealing surface flatness: ≤ 0.01 mm

- Surface roughness:

- Sealing surfaces Ra ≤ 0.8 μm

- Non-sealing surfaces Ra ≤ 1.6 μm

- Use new tools

- Low cutting depth

- Stable temperature control

7️⃣ Holes / Channels / Threads

- 5-axis positioned machining for angled holes

- Control burrs (Particle Control)

- Chamfer consistency before tapping

8️⃣ Deburring & Cleaning (Semiconductor Critical)

- 5-axis automatic chamfering

- Manual filing prohibited

- Ultrasonic cleaning

- DI water rinse

- Cleanroom packaging (Class 1000 / 100)

9️⃣ Surface Treatment (Semiconductor Spec)

- Common specs:

- White anodizing (Sulfuric / Oxalic)

- Hard anodize

- Electroless nickel (EN-P, low phosphorus)

📌 Post-treatment checks:

- Dimensions

- Coating thickness

- Hole position variation

5. Quality Inspection & Documentation (Critical for Equipment Vendors)

- CMM full-size measurement

- Vacuum leak testing

- Surface roughness report

- Material certificate (aluminum grade)

- Process flow / inspection report

6. Key Factors for Successful Semiconductor Aluminum Part Machining

✅ Single setup

✅ Stress control

✅ Particle management

✅ Cleaning and packaging

✅ Complete documentation

Semiconductor aluminum parts are not just “finished after machining”; success is defined by whether they can be installed into equipment and enter the process.

5-Axis Machining Process for Aluminum Alloys

From a practical manufacturing perspective, the following outlines a common and well-established 5-axis machining process for aluminum alloys, suitable for high-precision applications such as aerospace, semiconductor equipment, automotive, and optical components.

🔧 I. Material Selection (Common Aluminum Alloys)

Depending on the application, commonly used aluminum alloys include:

| Aluminum Alloy | Characteristics | Typical Applications |

|---|---|---|

| 6061-T6 | Good overall properties, excellent machinability | Structural parts, equipment components |

| 7075-T6 | High strength, harder material | Aerospace, load-bearing parts |

| 5052 | Excellent corrosion resistance | Sheet metal, enclosures |

| MIC-6 / ALCA-5 | Stress-relieved | Precision platforms, fixtures |

📌 6061 and 7075 are most commonly used for 5-axis machining, balancing machinability and rigidity.

⚙️ II. Overall 5-Axis Machining Workflow

1️⃣ Process Evaluation & Machining Strategy Planning

- 3D model analysis (freeform surfaces, chamfers, angled holes)

- Determine simultaneous 5-axis or 3+2 positional machining

- Define datums and machining orientations

- Evaluate tool interference and tool overhang

👉 Key advantage: Multi-face machining in a single setup

2️⃣ CAM Programming (5-Axis Toolpath Planning)

Common CAM software:

- Siemens NX

- Mastercam

- PowerMill

- HyperMill

Key CAM considerations:

- Tool orientation control (collision avoidance)

- Constant Z / constant stepover / flowline strategies

- Optimal cutting angle to reduce aluminum built-up edge

3️⃣ Fixturing & Workholding

Special considerations for aluminum:

- Avoid excessive clamping force to prevent deformation

Common solutions:

- Vacuum fixtures

- Soft jaws

- Customized 5-axis fixtures

📌 Single setup with multi-angle machining is standard in 5-axis processing

4️⃣ Rough Machining

Objective: Rapid material removal without deformation

- Tools: Large-diameter end mills, corner-radius cutters

- Strategies:

- High-speed machining (HSM)

- Adaptive / dynamic milling

Indicative cutting conditions:

- High spindle speed

- Medium to high feed rate

- Shallow depth of cut

🛠 Aluminum alloys are ideal for high speed and high feed machining

5️⃣ Semi-Finishing

Purpose:

- Correct deformation

- Leave uniform stock for finishing

- Maintain surface accuracy using 5-axis simultaneous control

Typical remaining stock: 0.2–0.5 mm

6️⃣ Finishing

Core precision process

Tools:

- Ball end mills

- Bull-nose cutters

Simultaneous 5-axis machining enables:

- Optimal cutting angle

- Reduced tool marks

Surface roughness:

- Ra 0.8–1.6 μm

- Optical components may achieve even finer finishes

📌 5-axis machining enables side cutting, resulting in superior surface quality

7️⃣ Hole Machining & Chamfering (Multi-Angle)

- Inclined and intersecting holes completed in one setup

- Automatic axis rotation

- High accuracy in coaxiality and positional tolerance

8️⃣ Deburring & Surface Treatment

- Automatic edge-following chamfering with 5-axis tools

- Reduced manual finishing

Post-processing options:

- Anodizing

- Hard anodizing

- Sandblasting + anodizing

- Chromate conversion coating

9️⃣ Quality Control (QC)

- Coordinate Measuring Machine (CMM)

- Surface roughness inspection

- Concentricity, flatness, and angular accuracy checks

🚀 III. Key Advantages of 5-Axis Aluminum Machining

✔ Reduced setups → higher accuracy

✔ Complex surfaces completed in one operation

✔ Simultaneous angled holes and chamfers

✔ Superior surface quality

✔ Significantly reduced cycle time

🧠 IV. Practical Machining Considerations

- Prevent chip accumulation → use high-flow coolant

- Apply anti-adhesion tool coatings (TiB₂ / DLC)

- Control thermal deformation

- Always perform full CAM simulation

#CNC Machining #Precision Machining #Positioning Accuracy #Machining Accuracy #CNC Machine Tools #5-Axis Machining #Precision Parts Machining #Automatic Machining Technology #CNC Machine Tool Accuracy

Loading and Unloading Machine Rails #AI Automatic Stacking Robotic Arm

#Yongyi Technology #Automatic Special Purpose Machine Manufacturing #Automatic Arm Handling and Loading #Automatic Inspection and Assembly

#Robotic Arm Suction Cup Gripper Series #CNC Precision Component Manufacturing #Semiconductor Automation Component Supply #Stainless Steel Aluminum Alloy Carbon Steel Copper Alloy

#Engineering Plastics #Sheet Metal Welding Assembly #Ceramic Quartz Machining #Customized Fixture Design, Manufacturing and Development #Customer Assembly Service

#Slide Table Fine Adjustment System #Digital Microscope #Aluminum Extrusion Trolley #Japan NPM Series Products

#Semiconductor Components #Automation Equipment Components #CNC Machining #Robotic Arm Loading and Unloading #Automatic Loading and Unloading Equipment #Smart Manufacturing #Automated Production Line #Smart Factory #Automation Equipment

#CNC Machining #CNC Precision Machining #Semiconductor Components #Automation Equipment #Precision Components #Robotic Arm #Stainless Steel Machining #Engineering Plastics #Ceramic Processing

Yong Yi Technology

Yong Yi Technology Co., Ltd. logo

Location: No. 188-9, Section 1, Dafeng Road, Tanzih District, Taichung City, Taiwan 42756, China

Call: +886-4-25341382

Ring Volume: +886-4-25341847

Email: yongyi-sales@umail.hinet.net

Email: justinwu6767@gmail.com

Post Author