“Comprehensive Guide to Common CNC Machining Materials: Metals, Plastics, and Composites with Properties and Applications”

Common CNC Machining Materials and Their Characteristics

1. Metals

- Aluminum Alloys: Lightweight, good strength, excellent thermal/electrical conductivity, corrosion resistant. Easy to machine, suitable for aerospace parts, automotive components, electronic housings, and heat sinks.

- Stainless Steel: High strength, excellent corrosion and heat resistance. Tough to machine, causes tool wear. Used in medical devices, food machinery, chemical equipment.

- Carbon & Alloy Steel: High hardness and strength, heat-treatable. Requires proper tooling and cooling. Applied in gears, shafts, molds, and mechanical structures.

- Copper & Brass: Excellent conductivity, antibacterial, easy to machine. Applications include connectors, heat exchangers, electronic parts, decorative pieces.

- Titanium Alloys: Lightweight, high strength, corrosion and heat resistant. Difficult to machine. Used in aerospace, medical implants, chemical equipment.

- Magnesium Alloys: Ultra-lightweight, good vibration damping. Easy to cut but flammable. Applied in aerospace, automotive, lightweight structures.

2. Plastics

- ABS: Tough, impact-resistant, low-cost. Used in prototypes, housings, mechanical parts.

- POM (Delrin): High rigidity, low friction, wear resistant. Ideal for gears, bearings, sliders.

- Nylon (PA): Tough, wear-resistant, chemical resistant. Common in gears, pulleys, mechanical parts.

- PEEK: High temperature resistance, strong, chemically resistant. Used in medical implants, aerospace, precision engineering.

- Acrylic (PMMA): High transparency, good aesthetics. Used in displays, optical parts, decorative panels.

- PVC: Corrosion and chemical resistant. Applied in pipes, housings, acid/alkali-resistant parts.

3. Composites

- GFRP: High strength, heat and corrosion resistance. Used in automotive parts, structural components.

- CFRP: Ultra-strong, lightweight, fatigue-resistant. Applied in aerospace, sports equipment, luxury automotive parts.

4. Key Considerations

- Mechanical properties

- Environmental resistance

- Machinability

- Surface finishing options

- Industry applications

CNC Common Materials Comparison Table: Properties, Machinability, Applications

| Category | Material | Key Properties | Machinability | Typical Applications |

|---|---|---|---|---|

| Metals | Aluminum Alloys | Lightweight, corrosion resistant, excellent conductivity | ★☆☆ Easy | Aerospace parts, automotive, electronic housings, heat sinks |

| Stainless Steel | High strength, corrosion & heat resistant | ★★★ Difficult | Medical instruments, food machinery, chemical equipment | |

| Carbon & Alloy Steel | High hardness, heat-treatable | ★★☆ Medium | Gears, shafts, molds, structural components | |

| Copper & Brass | Excellent conductivity, antibacterial | ★☆☆ Easy | Connectors, heat exchangers, electronic parts | |

| Titanium Alloys | Strong, lightweight, corrosion resistant | ★★★ Difficult | Aerospace, medical implants, chemical equipment | |

| Magnesium Alloys | Ultra-lightweight, good damping | ★★☆ Medium (flammable) | Aerospace, automotive, lightweight structures | |

| Plastics | ABS | Tough, impact resistant, low cost | ★☆☆ Easy | Prototypes, housings, mechanical parts |

| POM (Delrin) | Rigid, low friction, wear resistant | ★☆☆ Easy | Gears, bearings, sliders | |

| Nylon (PA) | Tough, wear & chemical resistant | ★★☆ Medium | Gears, pulleys, components | |

| PEEK | High strength, heat & chemical resistant | ★★★ Difficult | Medical implants, aerospace, precision engineering | |

| Acrylic (PMMA) | High transparency, aesthetic | ★☆☆ Easy | Displays, optical parts, panels | |

| PVC | Chemical & corrosion resistant | ★☆☆ Easy | Pipes, housings, chemical parts | |

| Composites | GFRP | High strength, heat & corrosion resistant | ★★☆ Medium | Automotive, structural parts |

| CFRP | Ultra-strong, lightweight, fatigue resistant | ★★★ Difficult | Aerospace, sports equipment, luxury cars |

Exhibition Investment Observation Report

Topic: CNC Machining × 2025 Taiwan Robotics & Smart Automation / Taipei International Automation Exhibition

1. Market Background

- Exhibition Positioning: Leading Asian industrial automation event, focusing on robotics, automation equipment, and smart manufacturing solutions.

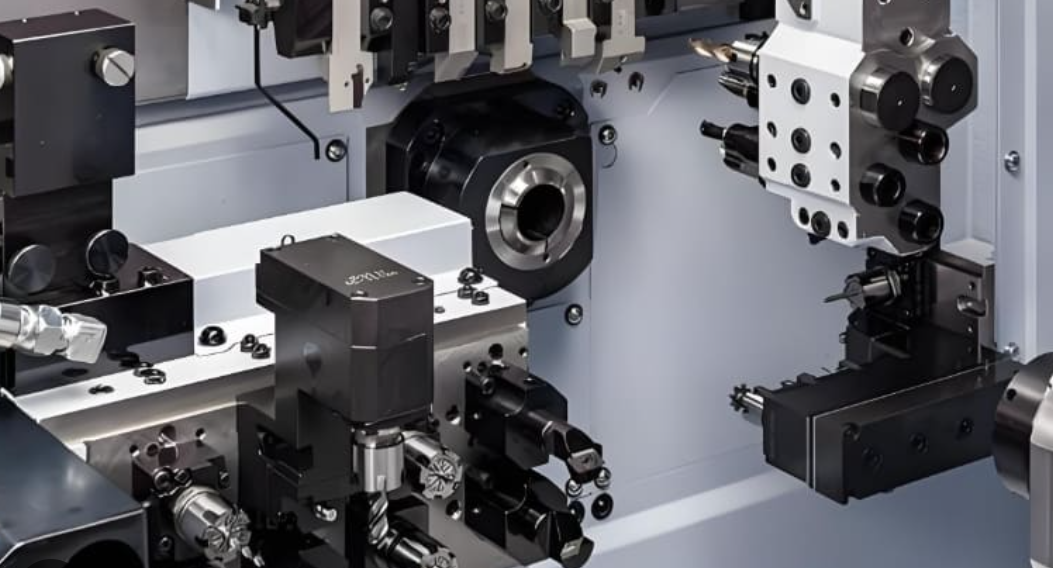

- Role of CNC Machining: Showcases multi-axis machining, digital integration, and unmanned production lines.

- Industry Relevance: High-precision parts are in demand for aerospace, automotive, medical, semiconductor, and green energy industries.

2. SWOT Analysis

| Category | Content |

|---|---|

| Strengths | High-precision, stable machining; highly integrable with robotics/automation; demonstrates intelligent manufacturing and MES connectivity. |

| Weaknesses | High investment cost for advanced CNC & automation; requires skilled personnel; high competition at exhibition. |

| Opportunities | International exhibition attracts buyers from Europe, US, Japan, Korea, SE Asia; rising demand in high-value industries; potential strategic alliances with automation integrators. |

| Threats | Global economic uncertainty; competition from China, Germany, Japan; rapid technology updates requiring continuous R&D. |

3. Market Opportunities

- Cross-industry Demand: Aerospace (composites, titanium parts), Medical (high-precision implants), Automotive & EV (lightweight structures, heat dissipation modules).

- Smart Factory Trend: CNC integrated with automated loading, inspection, and MES tracking; supports ESG and smart manufacturing.

- International Buyer Expansion: Direct connection with OEMs, ODMs, and SI integrators; opportunity to expand exports.

4. Strategic Recommendations

- Pre-exhibition: Prepare integrated solution demos: CNC + robotic arms + automatic inspection + MES connectivity; showcase cross-industry sample parts.

- During Exhibition: Establish alliances with international automation vendors; emphasize cost reduction, yield improvement, and unmanned manufacturing; live demos to attract high-level buyers.

- Post-exhibition: Collect customer data for product development; build long-term cooperation; strengthen international brand image.

Conclusion

CNC machining combined with smart automation and cross-industry applications will demonstrate core manufacturing + system integration, delivering market expansion, brand enhancement, and international cooperation advantages.

詠翊科技有限公司

location_on 42756 台灣台中市潭子區大豐路一段188-9號

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com