Precision Polishing Methods in CNC Machining: Applications and Overview

When discussing precision polishing in the context of CNC machining, the main goals are to improve surface finish, enhance dimensional accuracy, and meet both aesthetic and functional requirements — especially in areas such as mold making, optical parts, and medical components. Below is an introduction to several commonly used polishing techniques and their respective applications in CNC machining:

1. Manual Polishing

Characteristics:

- Uses hand tools such as polishing paste, sandpaper, abrasive stones, or buffing wheels.

- Relies heavily on the technician’s skill and experience; low efficiency but high flexibility.

CNC Machining Applications:

- Suitable for small-batch, high-precision molds and aesthetic parts.

- Commonly used for post-processing molds (e.g., plastic injection molds, die-casting molds).

- Ideal for local surface finishing or hard-to-reach areas.

2. Diamond Polishing Cloth

Characteristics:

- Cloth base embedded with diamond abrasives; suitable for hard materials such as carbide, ceramics, and hardened steels.

- Delivers high levels of surface finish, up to mirror-grade.

CNC Machining Applications:

- Used on precision parts or molds made of hard materials (e.g., cold work tool steels, powder metallurgy dies).

- Ideal for achieving ultra-smooth surfaces down to Ra < 0.05μm.

3. Diamond Paste Polishing

Characteristics:

- Uses polishing paste with diamond particles for high-precision surface finishing.

- Diamond grains range from a few microns to nanometers, allowing for mirror-like finishes.

CNC Machining Applications:

- Commonly used for optical molds and mirror-finish parts.

- Especially suitable for high-precision molds (e.g., lens molds).

- Widely applied in aerospace, medical instruments, and high-end tooling.

4. Ultrasonic Polishing

Characteristics:

- Utilizes high-frequency ultrasonic vibrations to drive a tool head for micro-polishing.

- Effective for narrow spaces, small features, and internal surfaces.

CNC Machining Applications:

- Perfect for micro components, complex 3D structures, deep grooves, and blind holes.

- Often used in medical implants, micro molds, and semiconductor tooling.

5. Electrolytic Polishing

Characteristics:

- Uses electrochemical reactions to remove surface peaks and smooth the metal surface.

- Suitable for stainless steel, titanium alloys, copper alloys, etc.

CNC Machining Applications:

- Applied to stainless steel components, medical tools, and food-grade machinery parts requiring ultra-clean, smooth surfaces.

- Enhances corrosion resistance and appearance.

6. Mirror-EDM Texturing

Characteristics:

- Achieves both polishing and texturing during Electrical Discharge Machining (EDM) using specific discharge parameters and electrode designs.

- Produces surfaces with high gloss and controlled textures, close to mirror quality.

CNC Machining Applications:

- Widely used in high-end mold making (e.g., mobile phone housing molds, automotive lighting molds).

- Reduces the need for separate polishing steps post-EDM.

- Suitable for mass production molds requiring high surface uniformity and quality.

🧩 Summary Table: Polishing Methods and Their Applications

| Polishing Method | Suitable Materials | Finish Level | Ideal Applications |

|---|---|---|---|

| Manual Polishing | Various metals | Medium–High | Small batch molds, local surface adjustments |

| Diamond Polishing Cloth | Hard metals, ceramics | High | Precision tooling, hard material molds |

| Diamond Paste Polishing | High-hardness metals | Ultra-High | Mirror-finish molds, optical parts |

| Ultrasonic Polishing | Fine features, cavities | High | Micro molds, blind holes, medical components |

| Electrolytic Polishing | Stainless, titanium, copper | High | Sanitary parts, corrosion-resistant components |

| Mirror-EDM Texturing | Tool steel, mold steel | High | Mold surfaces with mirror finish + texture design |

Use of Micro‑Milling + EDM + Polishing in CNC Machining: Methods & Applications

When the three techniques micro‑milling + EDM (Electrical Discharge Machining) + polishing are applied together in CNC machining, this represents a high‑precision process chain, typically for parts that are extremely fine, have complex shapes, and require high surface quality. Such a process is common in:

- Precision molds (e.g. optical lens molds, connector molds)

- Micro‑mechanical parts (MEMS, medical devices)

- High‑end electronics molds (camera lens frames, Type‑C connector molds, etc.)

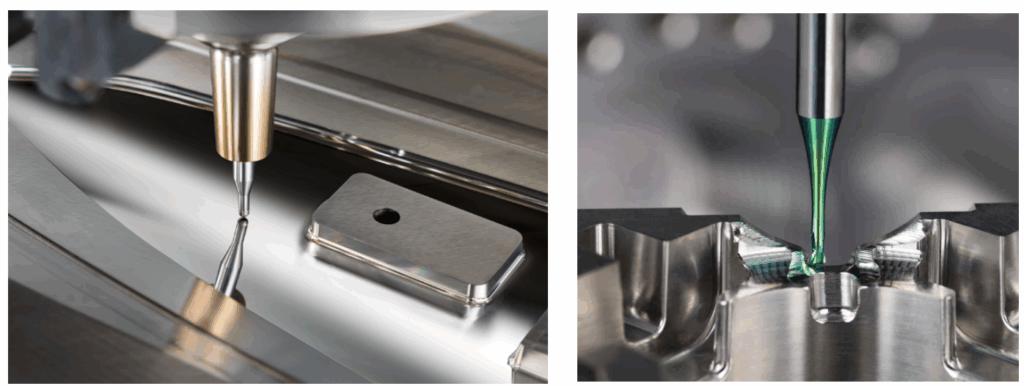

1. Micro‑Milling

Overview of the Technique:

- Uses tools with very small diameters (often < 1 mm), performing micron‑level material removal on CNC machines.

- Capable of creating very fine geometries or micro‑structures (micro‑holes, micro ribs, V‑grooves, etc.).

Application Methods:

- Often used for pre‑forming and defining fine features (micro edges, frames, connector regions).

- Can be applied to hard materials such as steel, tungsten carbide, copper alloys, ceramics.

- Useful to do roughing or preliminary shaping ahead of EDM, reducing EDM time by removing material first.

2. EDM (Electrical Discharge Machining)

Overview of the Technique:

- Material is removed via controlled electrical discharges (sparks) between an electrode and the workpiece.

- Good for machining very hard, electrically conductive materials or shapes that are hard to reach with cutting tools (deep cavities, internal corners, fine holes).

Application Methods:

- Used in places where micro‑milling cannot reach (deep micro‑holes, internal radii, undercuts).

- For producing micro structures, surface texture (especially using micro‑EDM milling, wire EDM, die‑sinking EDM).

- EDM is often slower and more costly per unit material removed, but yields high precision in complex / hard features.

3. Polishing

Overview of the Technique:

- After machining (micro‑milling + EDM), surfaces often have machining marks, recast layers (in EDM), small protrusions or irregularities; polishing improves surface finish.

- Methods may include mechanical polishing, ultrasonic polishing, diamond paste or cloth, electropolishing, mirror‑EDM (texturing + polishing), etc.

Application Methods:

- Polishing used to reach high surface quality (mirror finish, very low roughness, e.g. Ra < 0.05 µm)

- To reduce friction, improve release (in molds), improve optical performance, reduce burrs or defects.

- Especially important in internal surfaces (holes, blind holes) where EDM leaves rougher surface or recast layer.

Integrated Process Flow Example

- Micro‑Milling → define rough shape, fine features

- EDM → produce deep features, internal zones, fine contours that milling can’t reach

- Polishing → surface refinement, remove recast or roughness, achieve optical / mirror quality finish

Real‑World Use Cases

| Application Area | What is Made | Requirements & Details |

|---|---|---|

| Optical molds | Lens molds, LED reflector molds | Micro‑milling for profile, EDM for deep features, polishing for mirror finish |

| Medical device components | Surgical tools, implant molds | High precision + complex internal geometry + burr‑free surface |

| Electronics molds | Camera lens frames, connector molds | Dense fine features, uniform high surface quality, durability |

| Semiconductor precision parts | Test fixtures, pin molds | Extremely tight tolerances (±1‑2 µm), very smooth surfaces |

| Micro‑structure elements | Micro fluid channels, micro‑lens arrays, nano imprint molds | Micro‑milling for structure, EDM for texturing or internal features, polishing as final step |

Advantages Summary

| Technique | Strengths | Trade‑Offs / Considerations |

|---|---|---|

| Micro‑Milling | High resolution for small features; good 3D contour work | Tool fragility, tool wear, need for high speed & stiffness |

| EDM | Can reach deep / complex geometry; works on hard materials | Slower material removal; electrode wear; heat / recast layer must be managed |

| Polishing | Improves surface roughness; achieves mirror finish; removes defects | Additional cost/time; method selection depends on material, area, size |

#MicroMilling #EDM #Polishing #CNCMachining #PrecisionMachining #HighPrecisionManufacturing #MicroMachining #AdvancedManufacturing #OpticalMold #MedicalDevices #SemiconductorParts #ConnectorMolds #CameraMolds #LEDMolds #MEMS #Microfluidics #MicroFeatures #DeepHoleMachining #ComplexGeometry #MirrorFinish #SurfaceQuality #LowRoughness #RecastLayer #MoldRelease #3DContourMachining #TightTolerance #CarbideMachining #SteelMachining #CeramicMachining #CopperAlloys #UltrasonicPolishing #Electropolishing #MirrorEDM #MicroDrilling #MicroTools #ToolWear

詠翊科技有限公司

location_on 42756 台灣台中市潭子區大豐路一段188-9號

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com