CNC Precision Machining Experts|Aluminum, Steel, Stainless Steel, Engineering Plastics, Ceramics, and Quartz – All-in-One Solution

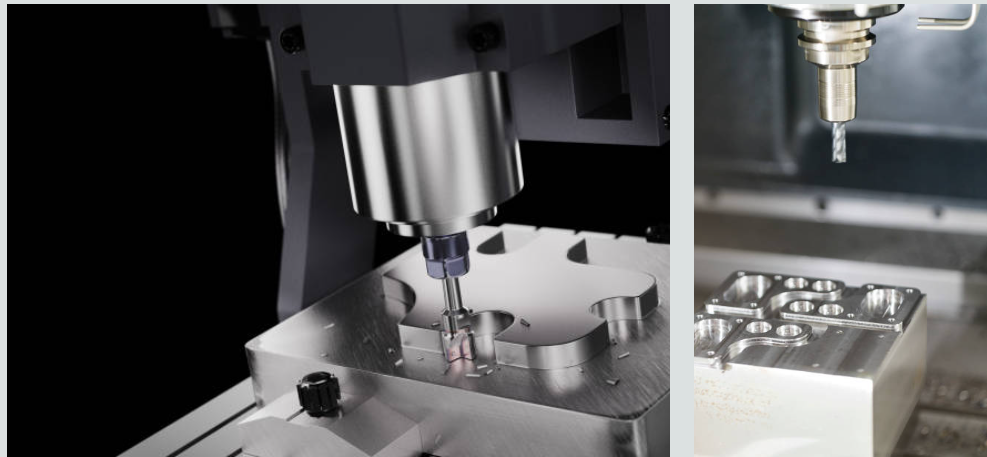

Professional CNC Machining Services – Yong Yi Tech Provides High-Precision Component Solutions

Founded in April 2005, Yong Yi Technology has over 20 years of CNC milling experience, dedicated to delivering high-precision and efficient machining services in the electronics, optics, and semiconductor automation industries. From prototyping to mass production, we meet diverse customer demands with stable quality and fast delivery.

Currently equipped with:

- 10 CNC milling machines

- 7 traditional milling machines

- Nearly 20 precision machines including lathes and surface grinders

We continuously expand our equipment and technical capabilities, actively introducing new machinery and automation solutions to increase capacity and broaden our service scope.

One-Stop Machining Integration|From Design and Development to Surface Treatment

Yong Yi Technology provides complete custom precision component development and mass production services, capable of designing and prototyping based on customer-provided 2D/3D drawings, and handling various post-processing and surface treatments, including:

- Anodizing

- Plating

- Surface sandblasting, polishing, laser engraving

- Material outsourcing / material supply assistance

- Strict quality inspection before delivery

From raw material processing to final packaging, everything is precisely managed by our internal team and professional partners, offering customers a worry-free one-stop machining experience.

Introduction & Advantages of CNC Machining Materials

1. Aluminum Alloy

🔹 Applications: Electronic housings, heat sinks, automation components, aerospace lightweight structures

🔹 Advantages:

- Lightweight, excellent thermal conductivity and heat dissipation

- Easy to machine with multiple surface treatment options (anodizing, sandblasting)

- Ideal for high-speed CNC milling, significantly reducing machining time

2. Carbon Steel / Alloy Steel

🔹 Applications: Mechanical parts, structural components, base fixtures

🔹 Advantages:

- High strength, suitable for load-bearing and structural applications

- Heat treatable for hardness and wear resistance

- Stable machining accuracy, ideal for high-load machine components

3. Stainless Steel

🔹 Applications: Medical instruments, food processing equipment, chemical equipment, cleanroom parts

🔹 Advantages:

- Excellent corrosion resistance and high strength

- Compatible with electropolishing, polishing, and laser engraving

- Suitable for industries requiring hygiene, cleanliness, and corrosion resistance

4. Engineering Plastics

🔹 Applications: Insulation parts, sliding bearings, protective windows, automation jigs

🔹 Advantages:

- Excellent insulation, wear resistance, and heat resistance

- Lighter and more cost-effective than metals

- Ideal for CNC machining of complex structural components

5. Ceramics / Quartz

🔹 Applications: Semiconductor, optoelectronics, precision optical instruments

🔹 Advantages:

- High heat and corrosion resistance, excellent thermal stability

- High difficulty to machine, but extremely precise results

- Ideal for special parts in extreme processing environments

Why Choose Yong Yi Technology?

✔ 20 years of CNC machining experience and expertise

✔ Comprehensive multi-material machining capabilities – from aluminum to quartz

✔ Rigorous quality control and reliable lead time, trusted by customers

✔ Flexible support for small-batch and multi-variety production

✔ Assistance with material selection, structural suggestions, and drawing optimization to enhance efficiency

📩 Contact us for your customized CNC machining quotation and technical consultation.

Yong Yi Technology – Your Professional Partner in Precision Machining!

Sujets connexes

Usinage CNC d’alliage d’aluminium|Léger, conductivité thermique élevée, prototypage rapide

Service d’usinage CNC professionnel|Le premier choix pour l’usinage cinq axes de haute précision

Des matières premières aux produits finis|Services de traitement de surface et de traitement CNC à guichet unique

Recommandation d’usine de traitement CNC|Équipe professionnelle de fabrication de pièces de précision à Taiwan

Usinage CNC #Usinage CNC #Usinage de précision #Précision de positionnement #Précision d’usinage #Machine-outil CNC #Usinage cinq axes #Usinage de précision de pièces #Technologie d’usinage automatisé #Précision de la machine CNC

Rail coulissant de machine de chargement et de déchargement #Bras robotisé d’empilage automatique AI

YongYiTech #Fabrication automatisée de machines spéciales #Manutention et chargement automatisés de bras #Tests et assemblage automatisés

Série de pinces à ventouse pour robot #Fabrication de composants de précision CNC #Fourniture de composants d’automatisation pour semi-conducteurs #Acier inoxydable, alliage d’aluminium, acier au carbone, alliage de cuivre

Plastiques techniques #Groupe de soudage de tôles #Traitement du quartz céramique #Conception, fabrication et développement de montages personnalisés #Service d’assemblage client

Système de réglage fin à platine coulissante #Microscope numérique #Chariot d’extrusion en aluminium #Produits japonais de la série NPM

composants semi-conducteurs #composants d’équipement d’automatisation #usinage CNC #chargement et déchargement de bras robotisés #équipement de chargement et de déchargement automatique #fabrication intelligente #ligne de production automatisée #usine intelligente #équipement d’automatisation

usinage CNC #usinage de précision CNC #composants semi-conducteurs #équipement d’automatisation #composants de précision #bras de robot #usinage de l’acier inoxydable #plastiques techniques #usinage de la céramique

Technologie Yongyi