In today’s field of precision manufacturing, not only are metal materials highly valued, but “plastic and ceramic CNC machining” has also become an indispensable process for producing high-performance components. Whether in medical devices, semiconductor equipment, chemical engineering, or the aerospace industry, engineering-grade plastics and advanced ceramic materials offer outstanding physical and chemical properties. With CNC precision machining, efficient and stable production becomes possible.

This article will provide a comprehensive explanation of this highly specialized CNC machining technology from five key perspectives: process principles, material types, equipment characteristics, machining challenges, and application areas.

1. Process Principles and Theoretical Foundations

1.1 Basic Principles of CNC Machining

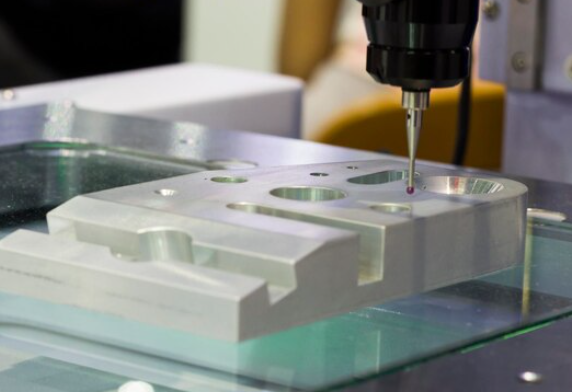

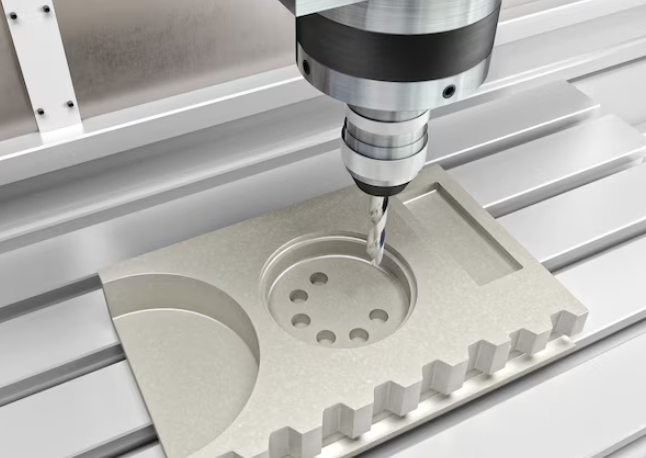

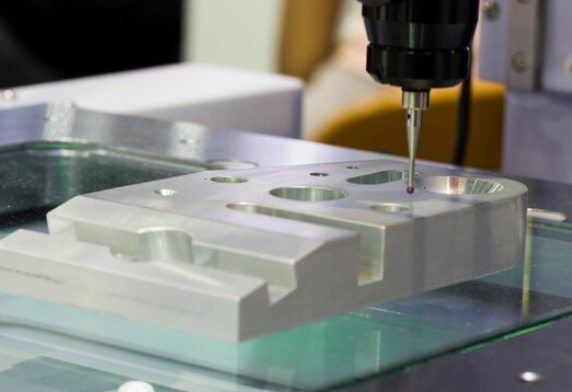

CNC (Computer Numerical Control) machining involves computer-programmed control of cutting tools, which move precisely along multiple axes to perform operations such as drilling, milling, and turning. When applied to plastics and ceramics, cutting parameters, tool materials, and machining strategies are adjusted based on material characteristics.

1.2 Machining Characteristics of Non-Metal Materials

- Plastic materials: Soft, poor thermal conductivity, high thermal expansion—prone to melting and burr formation.

- Ceramic materials: Hard and brittle, good thermal conductivity, wear-resistant, but non-ductile—prone to cracking during machining.

Therefore, machining strategies must be tailored to each material, such as using low feed rates, high spindle speeds, or ultrasonic-assisted methods.

2. Overview of Machinable Materials

▍Engineering Plastics

| Material | Properties | Common Applications |

|---|---|---|

| POM (Polyoxymethylene) | High strength, low friction, dimensional stability | Gears, sliders, jigs |

| PEEK (Polyether ether ketone) | High temperature resistance (up to 250°C), chemical resistance | Medical implants, aerospace parts |

| PTFE (Teflon) | Excellent lubricity, chemical corrosion resistance | Wet etching components, seals |

| PC (Polycarbonate) | High toughness, optical transparency | Protective covers, windows, optical parts |

| PEI (Ultem) | Strong insulation, flame retardant, stable | Electronic parts, connectors |

▍Technical Ceramics

| Material | Properties | Common Applications |

|---|---|---|

| Alumina (Al₂O₃) | High hardness, wear resistance, heat resistance up to 1600°C | Insulators, wear-resistant linings |

| Silicon Nitride (Si₃N₄) | High toughness, good thermal shock resistance | Turbine rotors, bearing components |

| Zirconia (ZrO₂) | Excellent toughness, low wear rate, low thermal conductivity | Medical implants, wear-resistant parts |

| Boron Nitride (BN) | Good thermal conductivity, electrical insulation | Semiconductor supports, furnace components |

3. CNC Equipment and Technical Requirements for Plastic and Ceramic Machining

3.1 Machine Tool Requirements

- High-speed spindles: Up to 30,000 RPM to reduce melting risk in plastics.

- Rigid structure with vibration-damping design: Especially important for machining brittle ceramics to prevent cracks.

- Ultrasonic-Assisted Machining (UAM): Enhances cutting stability for hard and brittle materials like ceramics.

- Precision cooling and dust collection systems: Prevent overheating in plastics or dust buildup from ceramics, ensuring accuracy and safety.

3.2 Tooling Techniques and Strategies

- Plastic machining: Sharp single-flute carbide tools, low feed rates, and air cooling.

- Ceramic machining: Use of diamond tools (PCD, CBN) or pre-slit cutting with lasers followed by machining.

4. Machining Challenges and Solutions

| Challenge | Solution |

|---|---|

| Plastic melting or burrs | Reduce spindle speed, use air cooling, polish edges with finishing tools |

| Ceramic chipping or cracking | Use ultrasonic machining, reduce cutting speed, preheat the workpiece |

| Difficulty in precision control | Scheduled tool replacement, tool offset compensation, precision fixtures |

| Thermal expansion or contraction | Maintain stable room temperature, reserve machining allowance |

5. Application Scenarios and Industry Use Cases

Engineering Plastic CNC Machining Applications:

- Semiconductor processing: PFA/PTFE wet etching equipment linings

- Medical devices: PEEK surgical implants, disposable diagnostic tools

- Food machinery: POM guide rails, PE fittings

- Automation equipment: PC/PEI control boxes, guiding components

Technical Ceramic CNC Machining Applications:

- Aerospace industry: Silicon nitride turbine components, zirconia thermal barriers

- Semiconductor wafer processing: Alumina wafer holders, boron nitride furnace components

- Precision instruments: Ceramic bearing housings, optical alignment blocks

- High-voltage applications: Alumina insulators, ceramic terminals

Conclusion | The Future Value of Non-Metal CNC Machining

As industries increasingly demand high performance, lightweight, and chemical-resistant components, plastic and ceramic CNC machining has become a key technology in modern manufacturing transformation.

Through the perfect integration of high-precision equipment, specialized tooling, and tailored machining strategies, we can produce engineering components that offer outstanding durability, stability, and cleanliness.

If you have machining needs for non-metallic materials, feel free to contact our professional team for prototyping and mass production collaboration!

Related topics

#Aluminum alloy CNC machining|Lightweight, high thermal conductivity, rapid prototyping

#Stainless steel CNC precision machining|Corrosion resistance and mirror electropolishing technology

#Five-axis CNC machining technology analysis|Complex surfaces and high-precision manufacturing

#CNC machining + electropolishing surface treatment|Medical-grade stainless steel applications

#Plastic and ceramic CNC machining|Engineering-grade non-metallic parts production solutions

#Professional CNC machining services|High-precision five-axis machining first choice

#CNC precision machining experts|Aluminum, steel, stainless steel done at one time

#High-quality CNC turning and milling|Fast delivery, high precision, stable mass production

#From raw materials to finished products|One-stop CNC machining and surface treatment services

#CNC processing plant recommendation|Taiwan precision parts manufacturing professional team

#CNC machining #CNC machining #Precision machining #Positioning accuracy #Machining accuracy #CNC machine tools #Five-axis machining #Precision parts machining #Automated machining technology #CNC machine accuracy

#Loading and unloading machine slide rail #AI automatic stacking robot arm

#Yongyi Technology #Automated special machine manufacturing #Automated arm loading and unloading #Automated inspection and assembly

#Robot suction cup gripper series #CNC precision component manufacturing #Semiconductor automation component supply #Stainless steel aluminum alloy carbon steel copper alloy

#Engineering plastics #Sheet metal welding group #Ceramic quartz processing #Customized fixture design, manufacturing and development #Customer assembly service

#Slide table fine adjustment table system #Digital microscope #Aluminum extrusion trolley #Japanese NPM series products

#Semiconductor components #Automation equipment components #CNC processing #Robot arm loading and unloading #Automatic loading and unloading equipment #Smart manufacturing #Automated production line #Smart factory #Automated equipment

#CNC processing #CNC precision processing #Semiconductor components #Automated equipment #Precision components #Robot arm #Stainless steel processing #Engineering plastics #Ceramic processing

#Yongyi Technology