Quartz Processing: Characteristics and Applications in the Semiconductor and Optical Industries

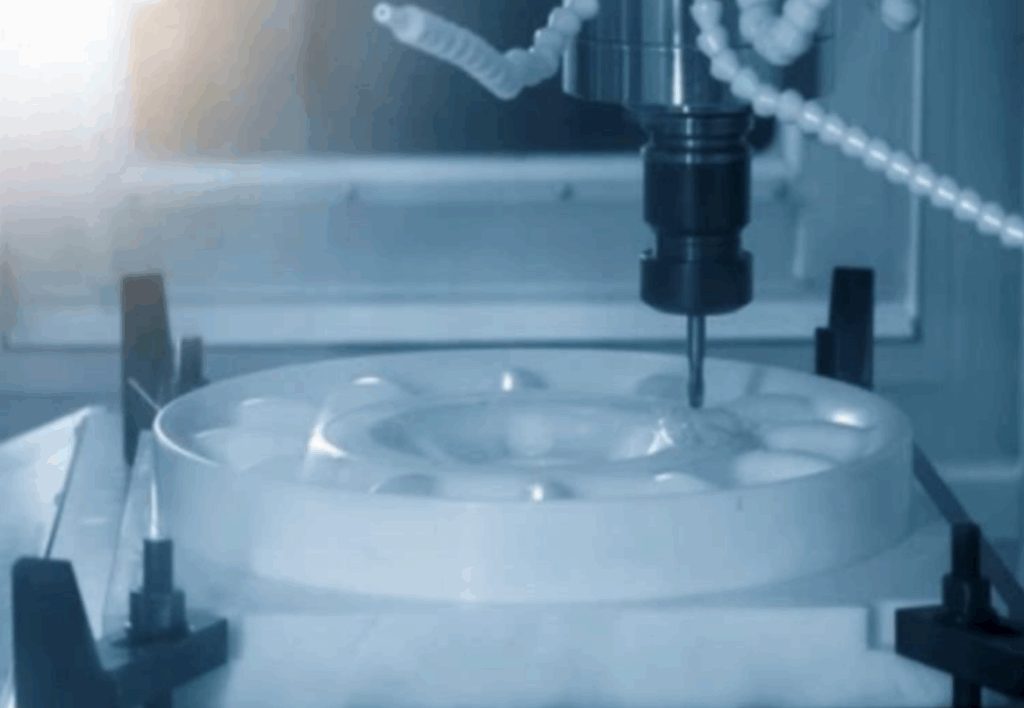

Quartz CNC refers to the technology of processing quartz materials using CNC machine tools (CNC). This includes milling and grinding of materials such as quartz glass, which is widely used in semiconductor, optoelectronics, solar energy and other industries.

- Quartz materials: Quartz materials, especially quartz glass, play a key role in many high-tech industries due to their excellent high temperature resistance, corrosion resistance, light transmittance and other characteristics.

- CNC processing: CNC machine tools (CNC) are equipment that automatically controls the tool for precise processing through pre-programmed CNC codes.CNC processing of quartz materials requires special tools and process parameters to ensure processing accuracy and quality.

- Application areas: Quartz CNC is mainly used to manufacture key quartz components in industries such as semiconductor equipment, optoelectronic equipment, and solar cells, such as quartz boats, quartz tubes, quartz rings, etc.

- Processing technology: Quartz CNC processing technology includes milling, grinding, polishing and other processes, which require professional technology and experience.

For example, Yong Yi Technology is a professional quartz CNC processing manufacturer that provides CNC OEM services for various quartz materials and has passed the ISO:9001 international quality management system certification. Yong Yi Technology focuses on the processing of quartz components and strives for excellence with “yield rate” and “delivery time” as indicators.

🔍 Properties of Quartz

Quartz, especially fused quartz or fused silica, is a highly valuable material in high-tech manufacturing. Key properties include:

| Property | Description |

|---|---|

| Ultra-high purity | Up to 99.99%, ideal for ultra-clean processing environments |

| Very low thermal expansion | Exceptional dimensional stability at high temperatures |

| High heat resistance | Melting point above 1700°C |

| Excellent optical transmission | High transmittance in UV, visible, and IR ranges |

| Superior electrical insulation | Suitable for electronics and semiconductors |

| High chemical stability | Resistant to corrosion from acids and alkalis |

🏭 Industrial Applications of Quartz

Quartz is widely used in industries requiring high purity, high temperature resistance, and precision, such as:

- Semiconductor manufacturing

- Optical and laser systems

- Aerospace and defense

- Laboratory equipment

- Solar and photonic devices

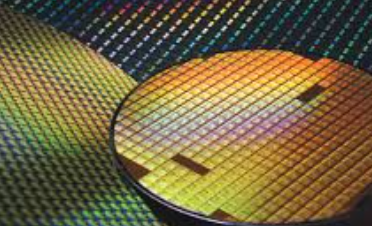

🧪 Applications in the Semiconductor Industry

Semiconductor processes demand extreme cleanliness and thermal stability. Quartz is used in:

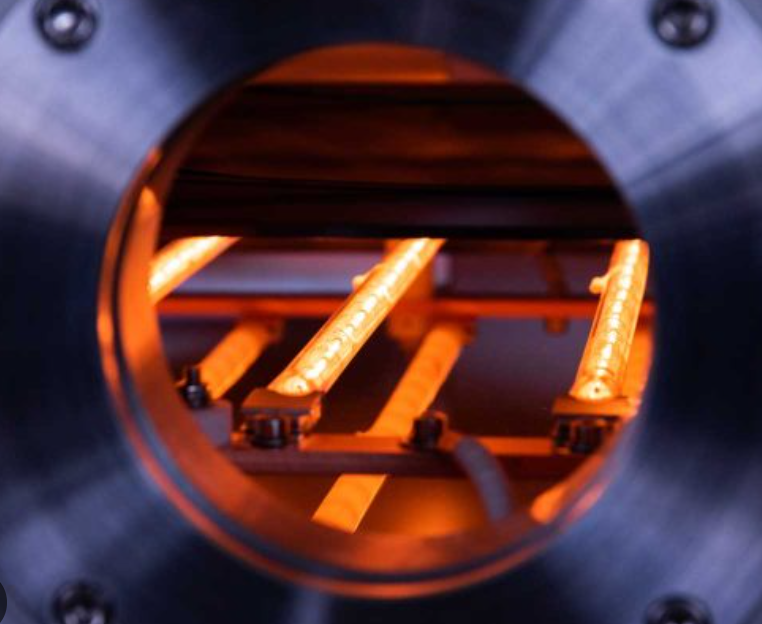

- CVD, LPCVD, and PECVD chambers

- Wafer boats and carriers

- Used in thermal processing (annealing, oxidation), quartz maintains structural integrity and insulation.

- Quartz lamp housings

- Quartz enclosures in UV and IR lamps for lithography and thermal processing.

- Etching and cleaning tanks

- Quartz is chemically stable, ideal for acid or Piranha cleaning baths.

🔬 Applications in the Optical Industry

- Optical lenses and windows

- High light transmittance and low dispersion make quartz perfect for precision optics.

- Laser components

- Quartz substrates ensure optical path stability in high-power laser systems.

- Optical fiber production

- Ultra-pure quartz is used as the core material in fiber optics for efficient data transmission.

⚙️ Quartz Processing Techniques

Quartz is hard and brittle, requiring special techniques:

| Method | Description |

|---|---|

| CNC with diamond tools | For precision cutting and shaping |

| Ultrasonic machining (USM) | Abrasive vibration cutting for fragile materials |

| Laser cutting | Accurate, though heat effects must be controlled |

| Polishing and grinding | Critical for optical-grade surfaces |

🧩 Conclusion

Quartz is a critical material in the semiconductor and optics industries due to its purity, thermal stability, and optical properties. With advancements in CNC and hybrid manufacturing, quartz’s precision applications continue to expand in modern technology.

#Quartz CNC Processing #Fused Quartz Application #Quartz Tube for Semiconductors #High Transparency Quartz for Optics #Precision Processing Quartz Components #Quartz Material Laser Processing Technology #High Temperature Resistant Quartz Carrier #UV Laser Optical Quartz Window #Silicon Dioxide (SiO₂)

#Loading and unloading machine slide rails #AI automatic stacking robot arm

#Yongyi Technology #Automated special machine manufacturing #Automated arm handling loading and unloading #Automated testing and assembly

#Robot suction cup gripper series #CNC precision component manufacturing #Semiconductor automation component supply #Stainless steel aluminum alloy carbon steel copper alloy

#Engineering plastics #Sheet metal welding group #Ceramic quartz processing #Customized fixture design, manufacturing and development #Customer assembly service

#Slide table fine-tuning table system #Digital microscope #Aluminum extrusion trolley #Japanese NPM series products

#Semiconductor components #Automation equipment components #CNC processing #Robot arm loading and unloading #Automatic loading and unloading equipment #Smart manufacturing #Automated production line #Smart factory #Automation equipment

#CNC processing #CNC precision processing #Semiconductor components #Automation equipment #Precision components #Robot arm #Stainless steel processing #Engineering plastics #Ceramic processing

Yongyi Technology