Engineering Plastics: POM, PEEK, PETP, NC NYLON, PPS, PC (transparent), Bakelite, Acrylic, Teflon / Applications

🔧 Engineering Plastics – Applications Overview

1️⃣ POM (Polyacetal / Acetal / Delrin)

Properties

- High rigidity and wear resistance

- Low friction coefficient

- Excellent dimensional stability

Typical Applications

- Precision gears, sliders, bearings

- Automation equipment components

- Jigs and locating pins

- CNC machine structural parts

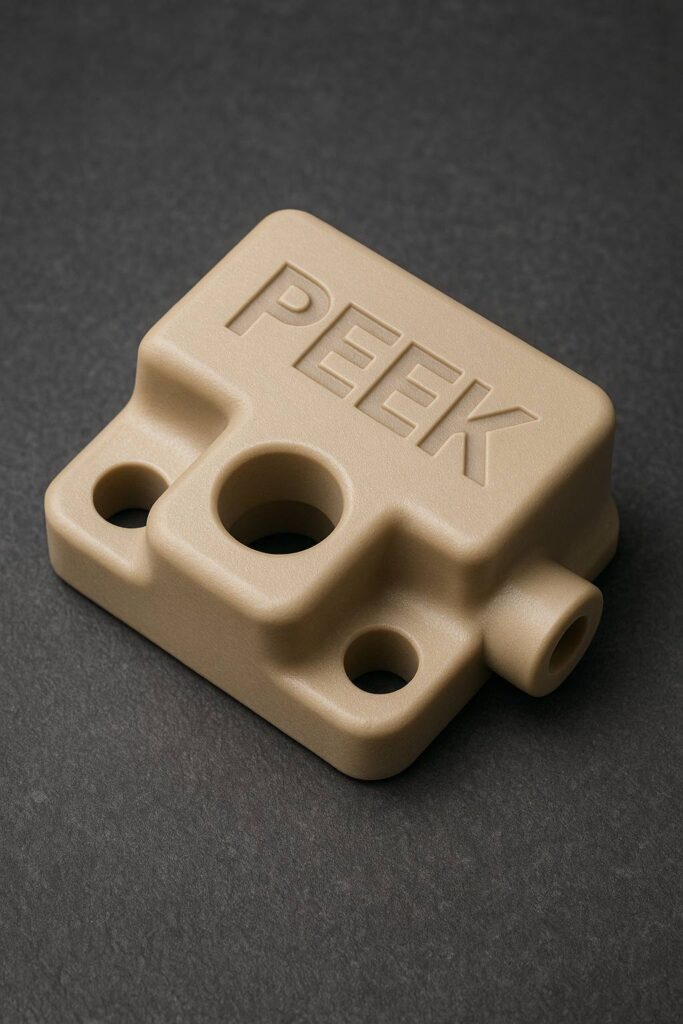

2️⃣ PEEK (Polyether Ether Ketone)

Properties

- High temperature resistance (continuous use up to 250°C)

- Excellent chemical resistance

- High strength, low outgassing (semiconductor-friendly)

Typical Applications

- Semiconductor equipment components

- Internal structures for vacuum chambers

- Medical devices and aerospace parts

- High-temperature electrical insulation components

3️⃣ PETP (PET / Ertalyte)

Properties

- Outstanding dimensional stability

- Low moisture absorption

- Good wear resistance

Typical Applications

- Precision sliders

- Electronic equipment parts

- Food machinery components

- High-precision CNC machined parts

4️⃣ NC Nylon (PA6 / PA66)

Properties

- High toughness and impact resistance

- Easy to machine, cost-effective

- Higher moisture absorption (tolerance control required)

Typical Applications

- Rollers and pulleys

- Machine guards

- Industrial jigs

- General mechanical components

5️⃣ PPS (Polyphenylene Sulfide)

Properties

- High temperature resistance (continuous use approx. 200°C)

- Excellent chemical and acid/alkali resistance

- High dimensional stability and fatigue resistance

Typical Applications

- Semiconductor equipment structural parts

- Electronic connectors

- High-temperature jigs

- Precision electrical components

6️⃣ Transparent PC (Polycarbonate)

Properties

- High transparency

- Excellent impact resistance

- Easy to machine (moderate scratch resistance)

Typical Applications

- Observation windows and protective covers

- Transparent machine covers

- Industrial safety guards

- Lighting covers and viewing panels

7️⃣ Phenolic / Bakelite

Properties

- Excellent electrical insulation

- Heat-resistant and flame-retardant

- High rigidity with brittle characteristics

Typical Applications

- Electrical insulation boards

- Distribution panel components

- Jig base plates

- Motor and electrical components

8️⃣ Acrylic (PMMA)

Properties

- Extremely high transparency (higher than glass)

- Excellent surface appearance

- Lower impact resistance

Typical Applications

- Display windows and observation covers

- Equipment viewing panels

- Control panels and signage

- Decorative components

9️⃣ PTFE (Teflon)

Properties

- Extremely low friction coefficient

- High temperature and chemical resistance

- Non-stick surface

Typical Applications

- Seals and gaskets

- Sliding bushings

- Chemical piping components

- Anti-adhesion parts for semiconductor equipment

📊 Quick Application Reference

| Material | Key Applications |

|---|---|

| POM | Precision mechanisms, gears, guide rails |

| PEEK | Semiconductor, high-temperature, high-purity |

| PETP | High precision, low moisture absorption |

| Nylon | General machinery, cost-effective |

| PPS | High temperature, chemical resistance |

| PC | Transparency, protection |

| Phenolic | Electrical insulation |

| Acrylic | Visual display |

| PTFE | Low friction, non-stick |

✅ CNC Material Selection Guidelines

- High precision & stability → PETP / POM

- High temperature & semiconductor equipment → PEEK / PPS / PTFE

- Transparent observation → PC (impact-resistant) / Acrylic (aesthetic)

- Electrical insulation jigs → Phenolic

Engineering Plastics: POM, PEEK, PETP, NC NYLON, PPS, PC (transparent), Bakelite, Acrylic, Teflon / Applications

- POM precision gears

- POM sliding parts

- POM bearings

- POM CNC machining

- POM low friction parts

- POM wear resistant components

- POM automation components

- POM mechanical parts

- POM industrial gears

- POM custom CNC parts

PEEK high temperature parts

PEEK chemical resistant components

PEEK CNC machining

PEEK vacuum compatible parts

PEEK electrical insulation

Industry/Applications

PEEK semiconductor parts

PEEK medical components

PEEK aerospace parts

PEEK high purity components

PETP precision machining

PET low moisture absorption parts

PET wear resistant components

PET dimensional stability parts

Industry/Applications

PET food machinery parts

PET electronic equipment parts

PET CNC machined components

Nylon CNC machining

Nylon rollers and pulleys

Nylon industrial parts

Nylon impact resistant components

Industry/Application

Nylon automation parts

Nylon mechanical components

Nylon general purpose parts

PPS high temperature components

PPS chemical resistant parts

PPS CNC machining

PPS dimensional stability parts

Industry/Application

PPS semiconductor equipment parts

PPS electronic connectors

PPS high temperature jigs

Transparent PC machining

PC protective covers

PC machine windows

PC impact resistant panels

Industry/Application

PC safety guards

PC CNC machined covers

PC industrial enclosures

Bakelite electrical insulation parts

Phenolic machining

Phenolic industrial boards

Bakelite CNC components

Industry/Application

Bakelite electrical components

Phenolic jigs and fixtures

Bakelite insulation blocks

Acrylic CNC machining

Acrylic transparent covers

Acrylic display panels

PMMA precision machining

Industry/Application

Acrylic machine windows

Acrylic equipment covers

Acrylic industrial display parts

PTFE low friction components

PTFE chemical resistant parts

PTFE high temperature seals

PTFE CNC machining

Industry/Application

PTFE semiconductor parts

PTFE sealing components

PTFE non-stick industrial parts

CNC machined plastic parts

Engineering plastics CNC machining

Custom plastic machining

Semiconductor plastic components

High precision plastic parts

Industrial plastic components supplier

Plastic CNC machining manufacturer

Yongyi Technology Co., Ltd.

location_on 42756 No. 188-9, Section 1, Dafeng Road, Tanzih District, Taichung City, Taiwan

Call: +886-4-25341382

Ring_Volume: +886-4-25341847

Email: yongyi-sales@umail.hinet.net

Email: justinwu6767@gmail.com