1. Role of Aluminum Alloys in Semiconductor Equipment

Aluminum alloys are widely used in semiconductor equipment primarily due to:

- Lightweight properties (reducing machine inertia)

- Excellent machinability (ideal for high-precision CNC machining)

- Good thermal stability (controllable thermal deformation)

- High surface treatment compatibility (Anodizing / Plasma processes)

👉 Aluminum alloys are mainly applied to non-reactive core process areas, yet are structural and chamber components located extremely close to the process zone.

2. Common Aluminum Alloys Used in Semiconductor Equipment

| Aluminum Alloy | Characteristics | Semiconductor Applications |

|---|---|---|

| 6061-T6 | Dimensionally stable, easy to machine | Structural parts, brackets, base plates |

| 7075-T651 | High strength and rigidity | Precision frames, motion modules |

| 5083-H112 | Excellent weldability | Vacuum chambers, enclosures |

| High-Purity Aluminum (4N / 5N) | Ultra-low contamination | Internal chamber components |

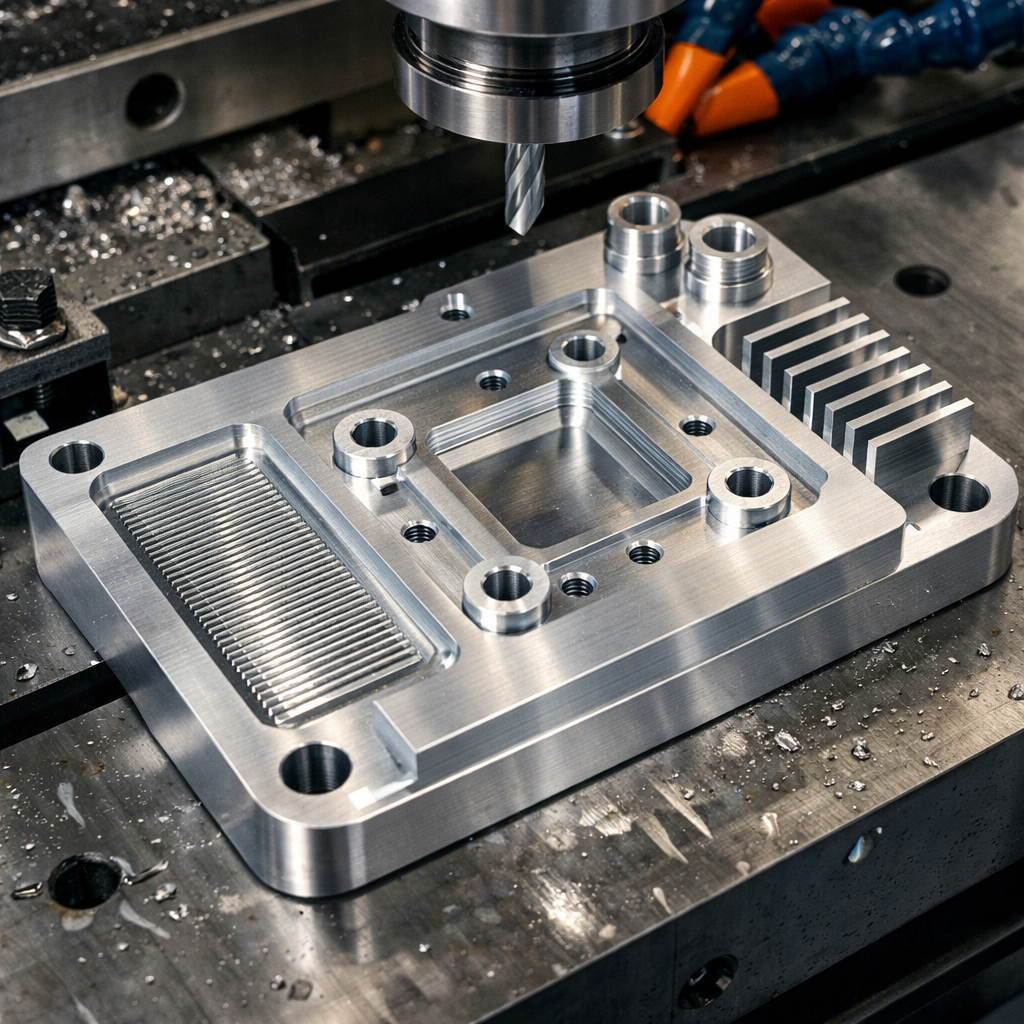

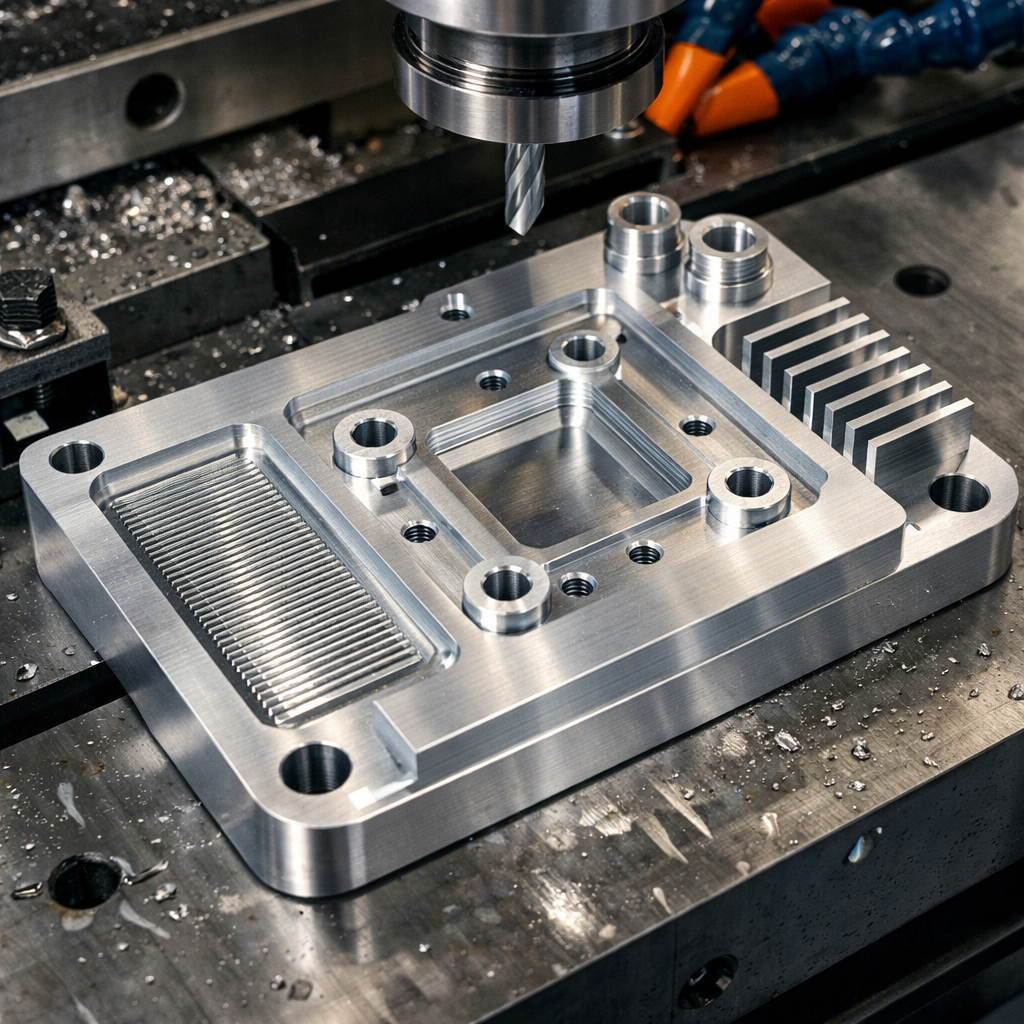

3. Machining Methods for Aluminum Alloys in Semiconductor Equipment

1️⃣ CNC Machining Technologies

Machine Types

- 3-axis / 4-axis CNC (flat surfaces, frames)

- 5-axis CNC (chambers, angled holes, complex flow paths)

- High-Speed Machining Centers (HSM)

Machining Strategies

- High-speed milling with low depth of cut

- Symmetrical machining to minimize internal stress

- Rough → Stress Relief → Finish

Tool Selection

- PCD tools (for high-purity aluminum)

- DLC / ZrN-coated end mills

- High chip-evacuation tool designs

2️⃣ Specialized Machining Processes (Common in Semiconductor Industry)

- Deep cavity machining (vacuum chambers)

- Complex flow channels (gas / cooling channels)

- Thin-wall structures (lightweight with high rigidity)

- High flatness machining (≤ 10 μm / 500 mm)

4. Standard Manufacturing Process Flow for Aluminum Semiconductor Parts

Material inspection (certification & batch traceability)

↓

Rough machining

↓

Stress relief (artificial / natural aging)

↓

Semi-finishing

↓

Finish machining (5-axis)

↓

Surface treatment (Anodizing / Plasma)

↓

Precision re-inspection (CMM / flatness)

↓

Ultrasonic cleaning (DI water)

↓

Cleanroom packaging (Class 100 / 1000)

5. Key Control Points for Semiconductor-Grade Aluminum Machining

1️⃣ Dimensional Accuracy & Thermal Deformation Control (Critical)

- Allowance for deformation must be reserved before machining

- Multiple stress-relief cycles for large components

- Temperature-controlled environment (20 ±1°C)

2️⃣ Surface Quality & Contamination Control

Surface Roughness

- General structural surfaces: Ra ≤ 1.6 μm

- Vacuum / gas contact surfaces: Ra ≤ 0.8 μm

Contamination Risks

- Sulfur-containing cutting fluids prohibited

- Separation of machining and cleaning areas

- Dedicated aluminum machining lines (avoid Fe contamination)

3️⃣ Surface Treatments (Core Semiconductor Technology)

| Surface Treatment | Function | Semiconductor Application |

|---|---|---|

| Hard Anodizing (Type III) | Wear & corrosion resistance | Structural components |

| Plasma Anodizing | Low particle generation | Internal chamber parts |

| Electroless Nickel (EN) | Gas tightness / sealing | Vacuum contact surfaces |

⚠️ Anodic layer thickness must be included in tolerance calculations (typically 20–50 μm).

4️⃣ Cleaning & Cleanliness Levels

- Ultrasonic cleaning (DI water)

- Cleanroom packaging (Class 100 / 1000)

- Low-outgassing packaging materials

6. Typical Applications of Aluminum Alloys in Semiconductor Equipment

Equipment Structure

- Equipment frames

- Base plates

- Motion module housings

Process Chambers & Internal Parts

- Vacuum chambers

- Liners / shields

- Gas distribution plates (non-high-temperature areas)

Auxiliary & Fixture Components

- Wafer carriers

- Alignment jigs

- Handling arm components

7. Aluminum vs. Other Materials (Semiconductor Perspective)

| Item | Aluminum Alloy | Stainless Steel | Ceramics |

|---|---|---|---|

| Machining Efficiency | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Cost | Low–Medium | High | Very High |

| Weight | Light | Heavy | Medium |

| Plasma Resistance | Medium | High | Very High |

| Application Area | Structures / Chambers | Gas / High-temp | Core processes |

8. Practical Recommendations for CNC Manufacturers

What German / Global Equipment Makers Value Most

- Dimensional repeatability

- Consistent surface treatment quality

- Clean process control capability

Recommended Capability Combination

- 5-axis machining + integrated surface treatment

- Experience in deformation control of large aluminum parts

- Semiconductor-grade cleaning processes

📌 Summary

Aluminum alloys are the “structural backbone” of semiconductor equipment.

The true value of CNC machining lies in stability × cleanliness × process integration.

I. Aluminum Alloy × Semiconductor [Core Keywords] Aluminum alloy, semiconductor equipment, semiconductor equipment aluminum components

Semiconductor aluminum components, Aluminum parts for semiconductor equipment

Semiconductor precision machining

Semiconductor equipment structural components

II. Material-Related Keywords (Aluminum Alloys) 6061-T6 aluminum semiconductor, 7075-T651 precision aluminum, 5083 aluminum vacuum chamber, High purity aluminum, 4N, 5N Semiconductor grade aluminum

High purity aluminum, semiconductor, aluminum alloy, material certification, Mill Certificate

III. CNC Machining Technology Keywords CNC aluminum machining, 5-axis aluminum machining, High speed milling, aluminum precision, CNC machining semiconductor, Aluminum deep cavity machining, Aluminum thin wall machining, CNC milling for semiconductor equipment

IV. Process and Quality Control Keywords Semiconductor manufacturing process control, Dimensional stability aluminum, Stress relief aluminum machining, Tight tolerance aluminum machining, ±5 micron precision machining, Thermal deformation control, Clean machining process

V. Surface Treatment and Cleaning Keywords (Key) Hard anodizing semiconductor Plasma Anodizing aluminum; Aluminum anodizing for vacuum; Chemical nickel plating; EN; Low particle surface treatment; Low outgassing aluminum; Semiconductor surface finishing

VI. Cleaning and Cleanroom Keywords: Ultrasonic cleaning; Semiconductor DI; Water cleaning; Cleanroom packaging; Class 100 Semiconductor clean process; Particle control machining

VII. Semiconductor Equipment Application Keywords: Vacuum chamber; Aluminum; Semiconductor equipment frame; Gas distribution plate; Aluminum; Wafer carrier; Aluminum; Semiconductor jig fixture; Precision aluminum housing

VIII. German Market / German SEO Keywords (Very Important): 🇩🇪 German Technical Keywords: Aluminiumkomponenten für Halbleiteranlagen CNC-Präzisionsbearbeitung; Aluminium; Aluminiumteile für Halbleiterindustrie 5-Achs-CNC-Aluminiumbearbeitung Hochreines; Aluminium Halbleiter Plasma-Anodisation; Aluminium Vakuumkammer; Aluminium

IX. Business and Cooperation Guiding Keywords Semiconductor equipment supplier Precision machining partner OEM supplier semiconductor Mechanical parts for semiconductor tools Global semiconductor supply chain Taiwan CNC semiconductor

Yongyi Technology Co., Ltd. de

location_on 42756 Nr. 188-9, Abschnitt 1, Dafeng Road, Bezirk Tanzi, Stadt Taichung, Taiwan

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com