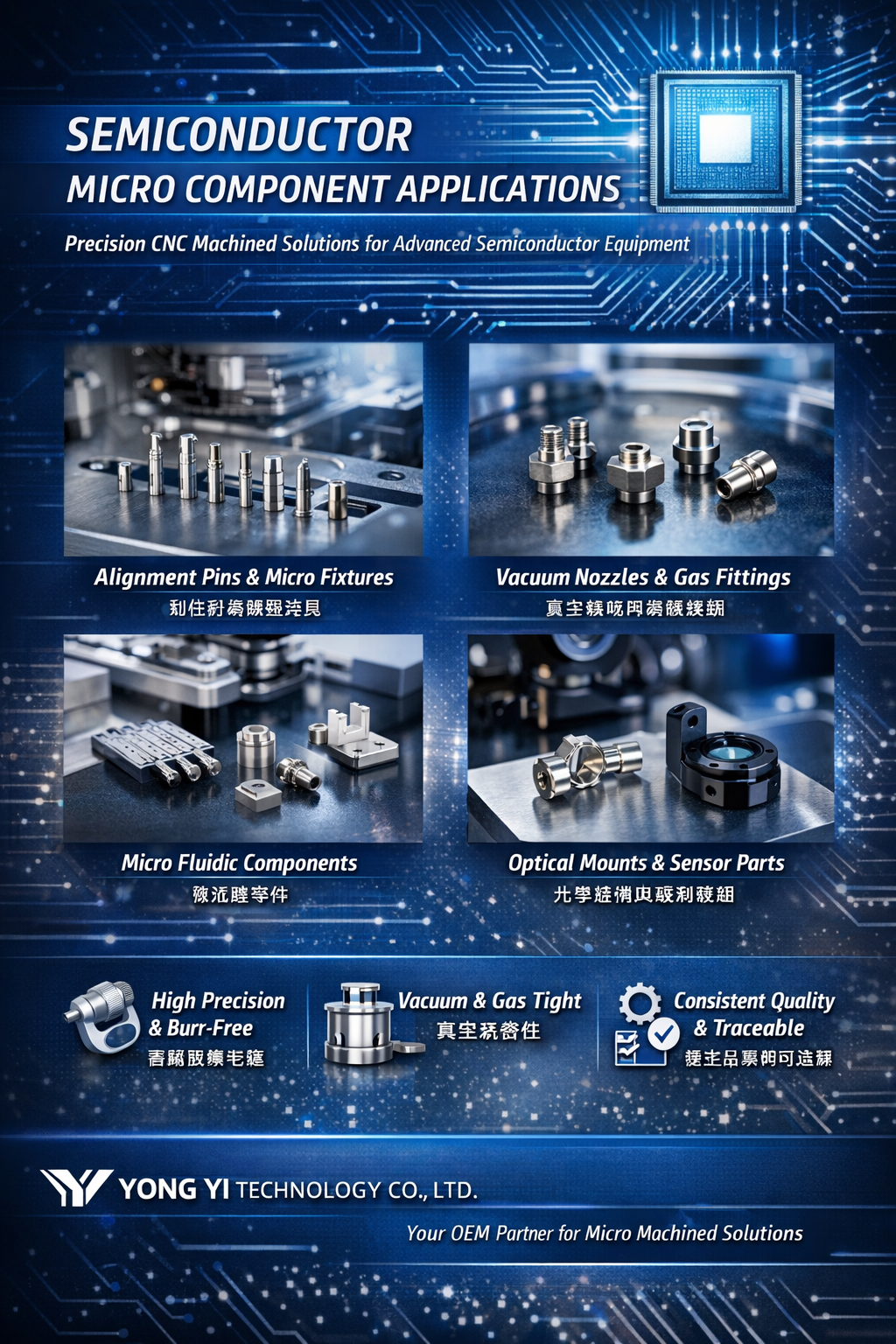

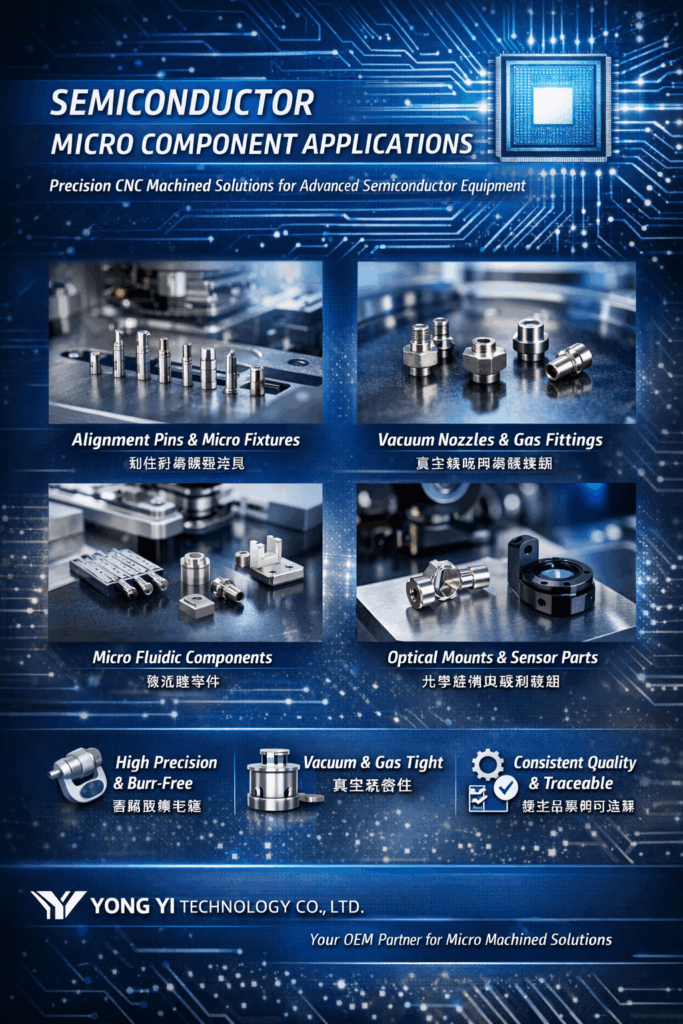

CNC Micro Precision Machining & OEM Services

I. CNC Micro Precision Machining

Service Positioning

Yong Yi Technology specializes in high-precision, small-size, and high-consistency CNC micro precision machining, suitable for:

- Semiconductor equipment components

- Optical and precision instruments

- Automation and medical devices

- High-end mechanical parts and fixtures

Typical Machining Capability

- Part size: Ø1 mm – Ø50 mm

- Micro-hole machining: from Ø0.2 mm

- Tolerance control: ±0.002 – ±0.005 mm (depending on material and geometry)

II. Core Capabilities for Micro Precision Machining

1️⃣ Equipment & Machine Configuration

To ensure stability and repeatability for micro parts, Yong Yi Technology is equipped with:

- High-speed CNC machining centers (spindle speed 20,000–40,000 rpm)

- High-rigidity linear guides and roller ball screws

- Dedicated micro-tool holders (Shrink Fit / Hydraulic Chuck)

- 5-axis machining capability to minimize repositioning errors

Core Objective:

Complete machining in a single setup to eliminate cumulative tolerances.

2️⃣ Dedicated Process Design for Micro Parts

In micro machining, Yong Yi Technology prioritizes stability and repeatability rather than speed:

- Optimized machining sequence (rigidity first, precision later)

- Low cutting force strategies (micro depth of cut / micro feed rate)

- Thermal compensation and machine temperature stability control

- Dedicated fixtures and vacuum clamping systems

Key Focus Areas:

- Deformation control

- Burr management

- Edge quality and surface integrity

3️⃣ Material Processing Capability

Yong Yi Technology supports a wide range of materials for micro precision components:

Metals

- Stainless steel (SUS304 / 316 / 420)

- Aluminum alloys (6061 / 7075)

- Copper alloys and brass

- Titanium (small batch, high precision)

Engineering Plastics

- PEEK

- POM

- PET

- PTFE (special fixtures and applications)

III. Quality Control & Inspection

Measurement & Inspection Systems

To meet European and semiconductor equipment standards, Yong Yi Technology implements:

- Optical / micro vision measurement systems

- High-precision Coordinate Measuring Machines (CMM)

- Surface roughness (Ra) inspection

- First Article Inspection (FAI) and In-Process Quality Control (IPQC)

Documentation Available

- Inspection reports

- Material certificates (Mill Certificates)

- Full batch traceability and process records

IV. OEM Service Model

OEM Is More Than Manufacturing — It Is a Technical Extension

Yong Yi Technology provides OEM services in four levels:

1️⃣ Build-to-Print Manufacturing

- Customer-supplied 2D / 3D drawings

- Full responsibility for process planning, machining, and inspection

- Strict compliance with DIN / ISO / SEMI standards

✔ Ideal for European equipment manufacturers with established designs

2️⃣ DFM / DFA Co-Development Support

- Manufacturability analysis for micro precision parts

- Optimization of:

- Tolerance allocation

- Machining strategy

- Cost and yield

✔ Allowing customers to focus on core technologies while Yong Yi handles manufacturing execution

3️⃣ Module & Sub-System OEM

- Multi-part integrated machining

- Surface treatments (Anodizing / Passivation / PVD)

- Pre-assembly and functional testing

✔ Delivered ready for direct equipment integration

4️⃣ Long-Term Serial Production & Export OEM

- Prototype → small batch → stable mid-volume production

- Batch control and revision management

- Export support for Europe, USA, and Japan

V. Differentiation & Value Proposition

Yong Yi Technology emphasizes technical value rather than low pricing:

- 🔧 Expertise in high-difficulty, non-standard micro components

- 📐 Stable dimensional consistency in series production

- 🧠 Deep understanding of semiconductor and high-end equipment requirements

- 🌍 Familiarity with European OEM cooperation models

- 📦 Capability from prototype development to long-term supply

#Pemesinan Mikro-Bahagian CNC #PemesinanCNCKetepatan #PemesinanKetepatan Peringkat Mikro #KomponenKetepatanTinggi #KomponenPeralatanSemikonduktor #KomponenMikroSemikonduktor #PemesinanCNCMketepatan #PemesinanMikroCNC #PemesinanMikroKetepatan #PemesinanKetepatanOEM #PembuatanOEM #PerkongsianOEMP #BinaUntukMencetak #SokonganDFMS #PemesinanPeralatanSemikonduktor #KomponenSistemVakum #KomponenMikroBendalirGas #PemesinanLubangMikro #PemesinanBebasBurr #PengeluaranJisimKetekalanTinggi #MetrologiKetepatanCMM #PengurusanKebolehkesananProses #PemesinanPlastikKejuruteraan #PemesinanPEEK #PemesinanPOMMakin #Tahan Karat

#Head of Procurement

#Buyer / Purchasing Manager

#Supply Chain Manager

#R&D / Mechanical Engineering Lead

Yongyi Technology Co., Ltd.

location_on 42756 No. 188-9, Section 1, Dafeng Road, Tanzi District, Taichung City, Taiwan

email yongyi-sales@umail.hinet.net

email justinwu6767@gmail.com