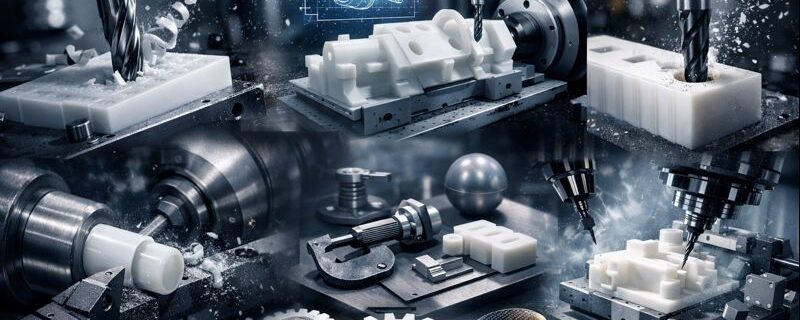

CNC Micro Precision Machining & OEM Services

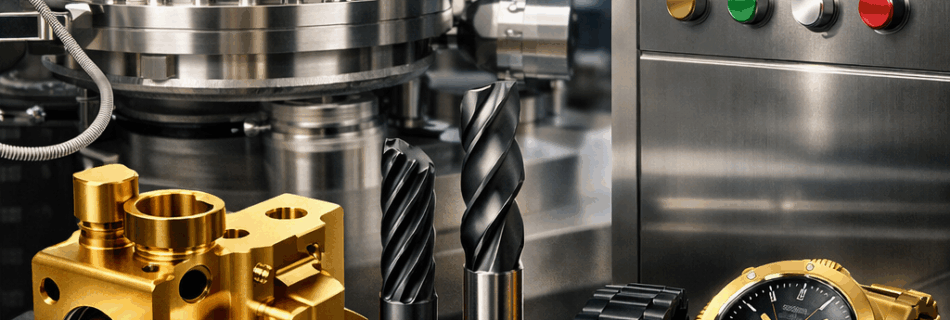

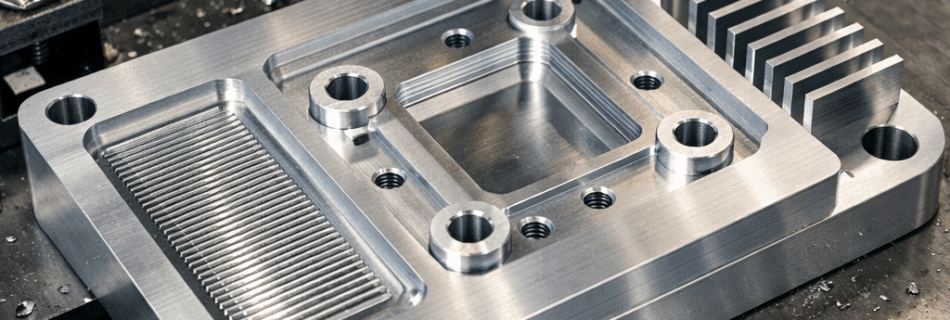

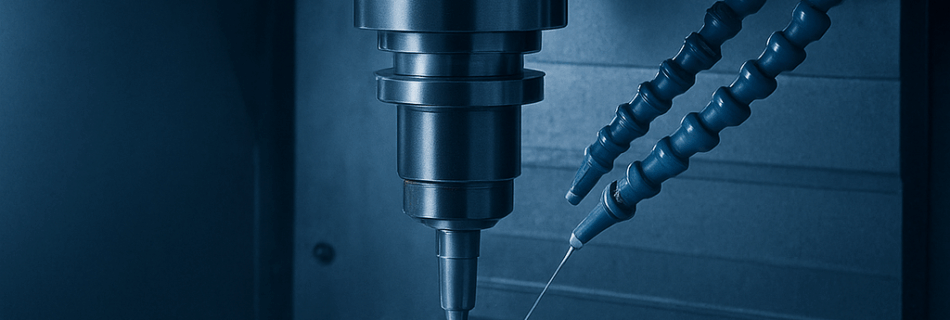

CNC Micro Precision Machining & OEM Services I. CNC Micro Precision Machining Service Positioning Yong Yi Technology specializes in high-precision, small-size, and high-consistency CNC micro precision machining, suitable for: Typical Machining Capability II. Core Capabilities for Micro Precision Machining 1️⃣ Equipment & Machine Configuration To ensure stability and repeatability for micro parts, Yong Yi Technology …