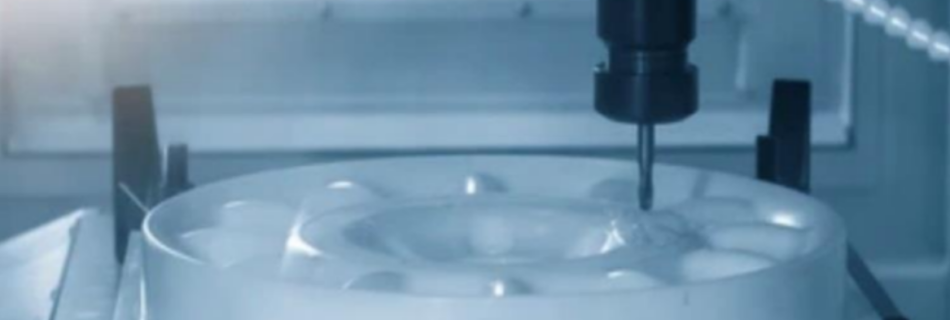

Laser Processing in the CNC Industry

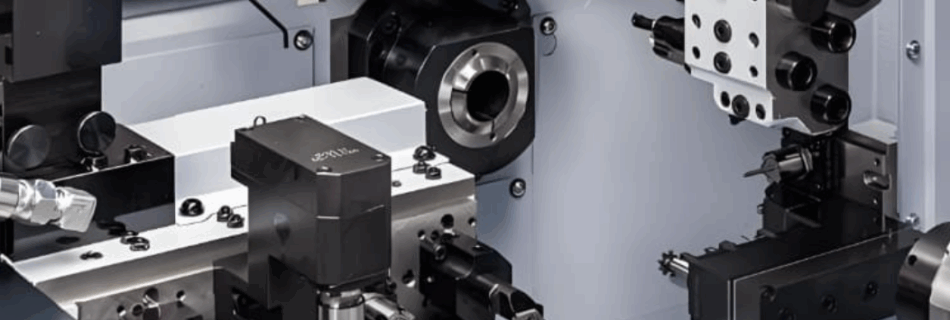

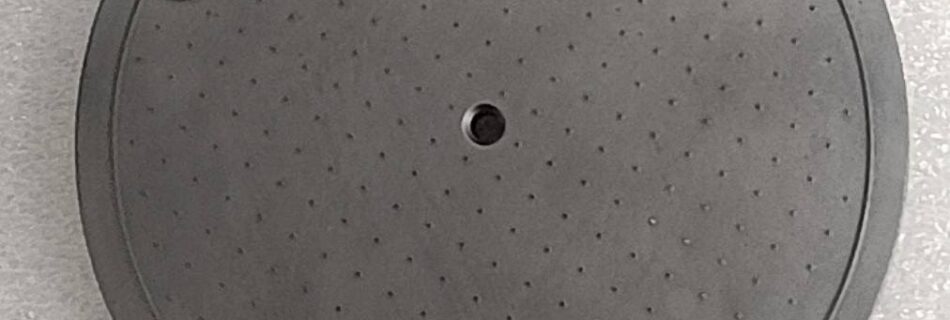

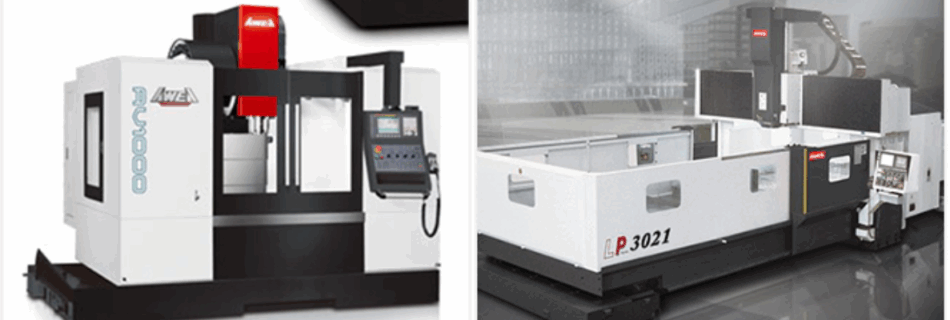

Laser Processing in the CNC Industry Positioning vs. Milling/Turning/EDM Laser Types & Applications Main Processes Integration with CNC Parameters & Quality Applications Safety & Maintenance Stainless Steel Color Laser Engraving Principle Process Characteristics Applications Advantages Limitations LaserProcessing #CNCmachining #LaserCutting #LaserEngraving #StainlessSteelMachining #PrecisionManufacturing #SmartManufacturing #FiberLaser #LaserWelding #MicroMachining #MetalMachining #CNCIntegration #AutomatedMachining #SurfaceTreatment #LaserMarking #5AxisMachining #LaserApplications #AdvancedManufacturing #IndustrialAutomation …